Reputable and reliable prototyping mold making company

In this issue, we will discuss which companies in the world that manufacture prototype molds are more reliable and trustworthy?

First of all, we need to know what the purpose of so many bosses or engineers is to design the prototype, and what value they want the prototyping to achieve.

Generally most people know that the purpose of making a prototype mold is usually the following two points.

First, the products that the company has just developed or designed are inevitably going to be prototypes. Prototypes are the first step to verify the feasibility of the products. To make targeted improvements, it is worth noting that some complex products cannot find all the deficiencies from individual prototype samples, or it can be confirmed that there are no problems by making a few more models. Therefore, it is usually necessary to carry out small batches. Trial production to find out the deficiencies in the batch and then make improvements.

Second, the product from design to completion generally cannot be completed in one step, perfect, or even unusable. If the company directly conducts mass production, once it has defects, it will all be scrapped, which greatly wastes manpower, material resources and time; and the prototype is generally a minority The production cycle is short and the loss of manpower and material resources is small, and the deficiencies of the product design can be quickly found and improved, providing sufficient basis for the mass production of product stereotypes.

So when we have the design drawings, who do we turn to for production? There are all kinds of prototype mold manufacturers on the market, how can we find a reliable and cost-effective prototype manufacturer?

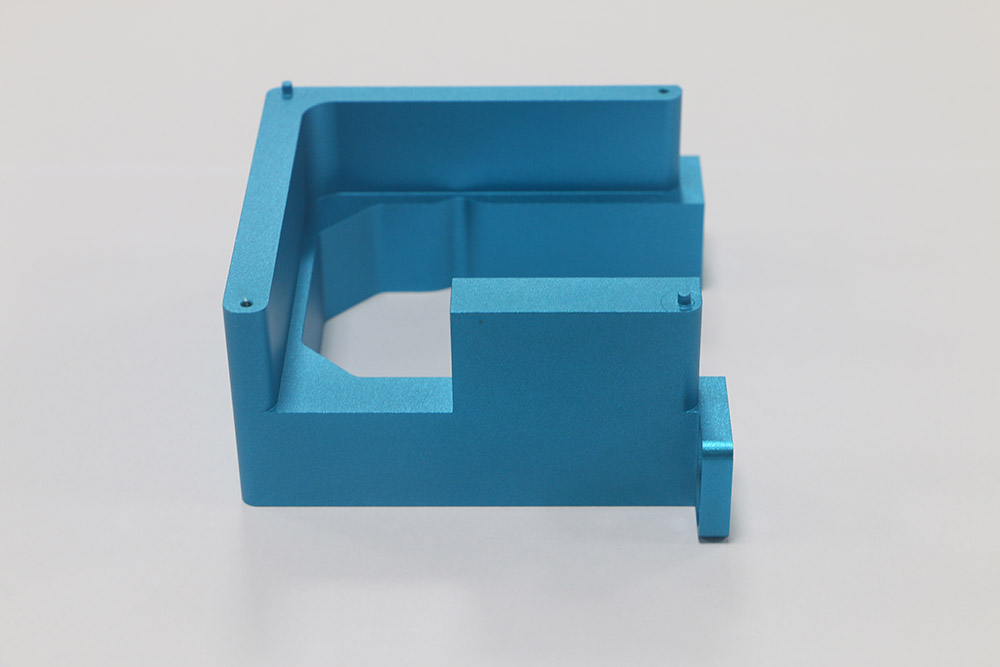

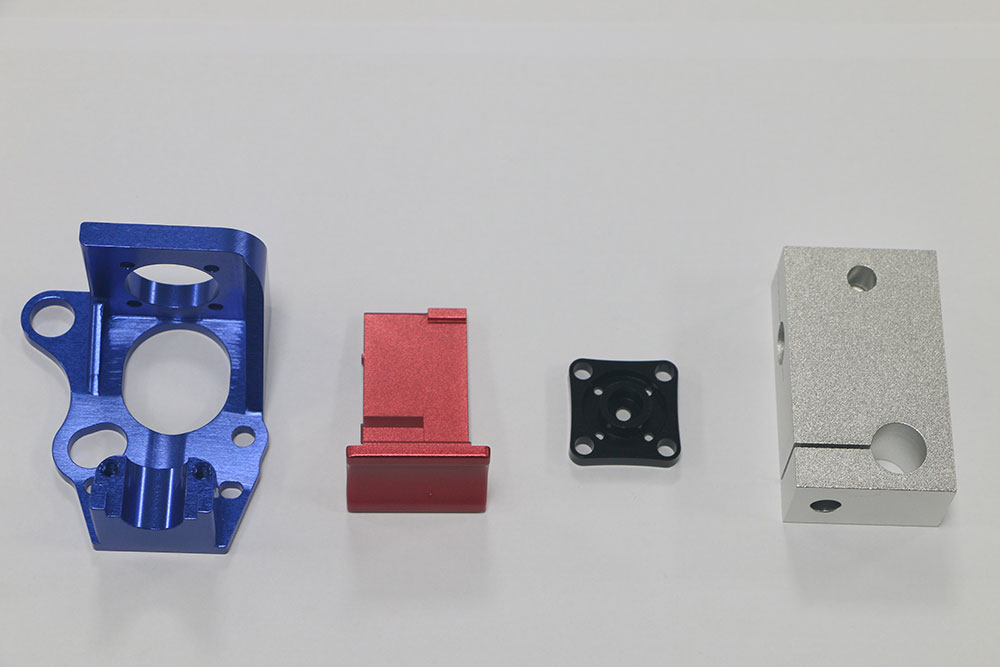

Personally, I don’t think a reliable supplier is the bigger the better or the more expensive the better. There are many processing methods for making prototypes, including CNC processing, 3D printing, vacuum casting, and mold opening. The process effect that each processing method can achieve is different, so the cost is also different. We first need to determine what the size of the prototype mold is, what quantity it needs to be made, how much tolerance needs to be controlled, and how high precision needs to be achieved, and then make 3D drawings based on these standards, and then send it to the supplier for inquiry. Then, a professional supplier will recommend a most cost-effective processing method to you after performing engineering analysis based on your 3D drawings.

In general, Reliable and Reliable Prototype Mold Manufacturing Company has been in in this industry for many years. They add different types of processing methods and upgrade processing techniques based on feedback from the market and customers. Let customers have a variety of choices in choosing processing technology and cost for their prototyping.

Of course, before deciding whether the selected supplier is trustworthy, we can first check the company’s project cases online to see what its customers say about it. Here I recommend 2fprototypes – a prototyping mold manufacturing company in China, there are a variety of processing technology to choose from. Click Here to see the real feedback from its customers.

Keyworld: #prototyping #CNCmachining