Welcome to 2fprototypes!

Focus on the processing and manufacturing services of prototypes and molds

Professional manufacturing personnel, focusing on efficient delivery

We have served over 4,500 customers and won wide recognition and praise

Covering a variety of processing needs and industry applications

We provide end-to-end manufacturing services including CNC machining,

mold making, injection molding, sheet metal fabrication, 3D printing, vacuum casting,

and surface finishing — covering both prototypes and low-volume production.

We provide advanced manufacturing for medical devices, automotive, consumer

electronics, robotics, aerospace, industrial automation, and more.

We help you successfully implement each of your projects with professional,

stable and efficient manufacturing services.

From prototyping to mass production — we handle it all, including surface finishing, quality inspection, and global shipping. Save time and reduce hassle.

We support a wide range of materials and processing methods to meet various needs across different industries.

We care about every detail:Clear communication during pre-sale Timely updates throughout production Follow-up after delivery — until you are fully satisfied

Send us your drawings or requirements — we’ll respond within 24 hours.

of industry

experience

CNC, injection molding, 5-axis machining, cleanroom production, and more — all under

one roof to ensure quality, speed, and flexibility.

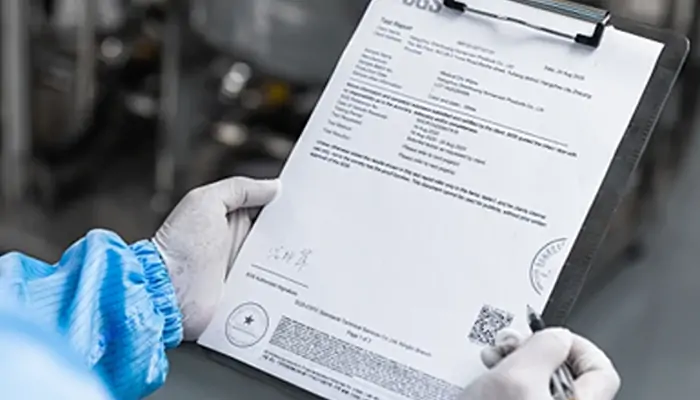

We are equipped with advanced dimensional inspection equipment, including height gauges, visual measuring systems, and CMMs, to ensure product accuracy and consistency.

All products undergo strict in-process and final inspections. We provide official quality reports with key dimension data to ensure traceability and verify compliance with your specifications.

Before delivery, we'll send you detailed product photos along with packaging details and quantity information for your approval. Shipment will proceed only after we receive your confirmation.

One-to-one follow-up, quick response to every step

Describe project details and upload CAD files.

Our engineers assess the details and provide confirmation.

Secure payment initiates your project.

Your custom parts are being manufactured with precision.

We ship the finished parts safely and promptly.

Check your parts upon arrival — if any adjustments are needed, we’re here to help.

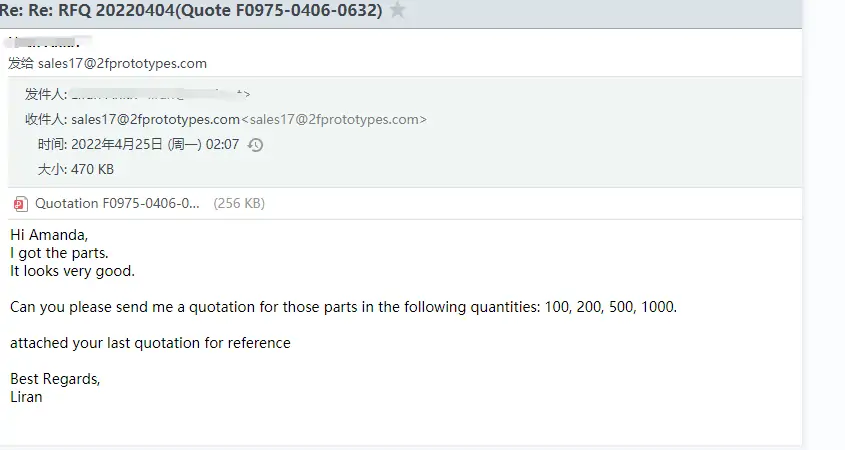

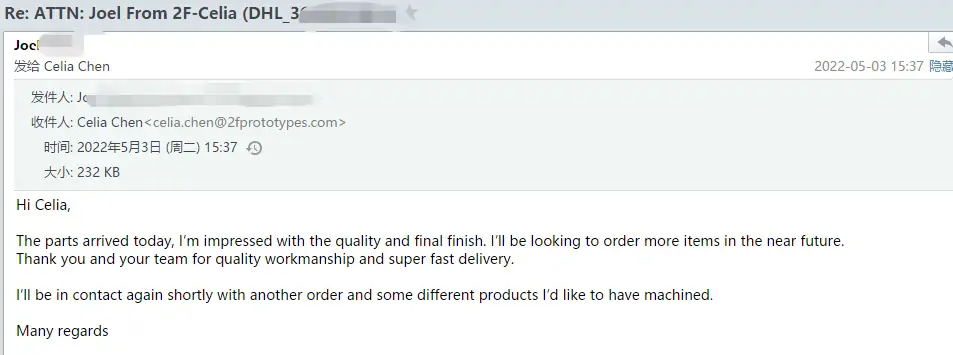

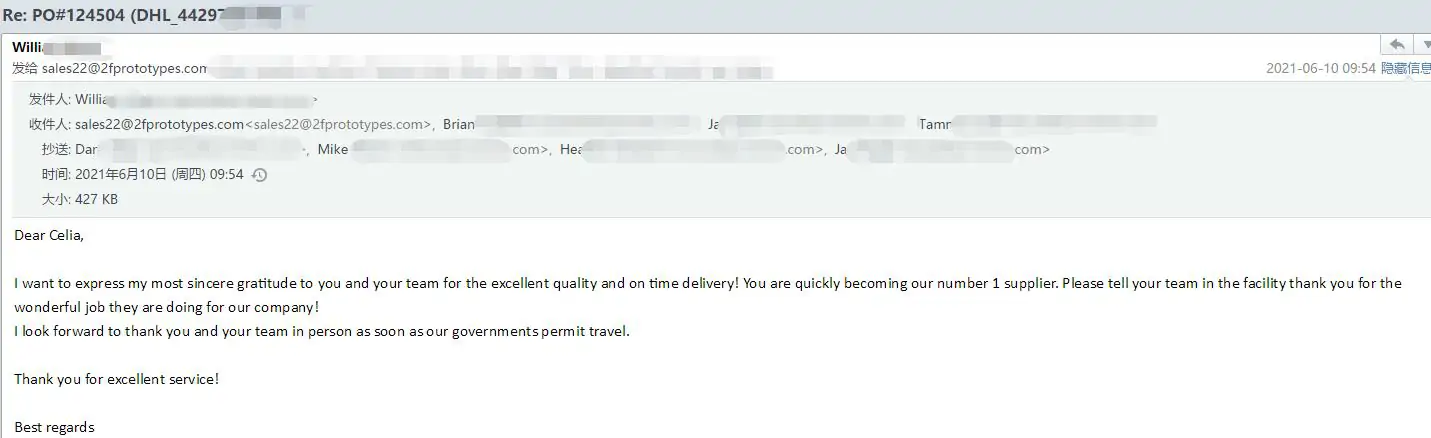

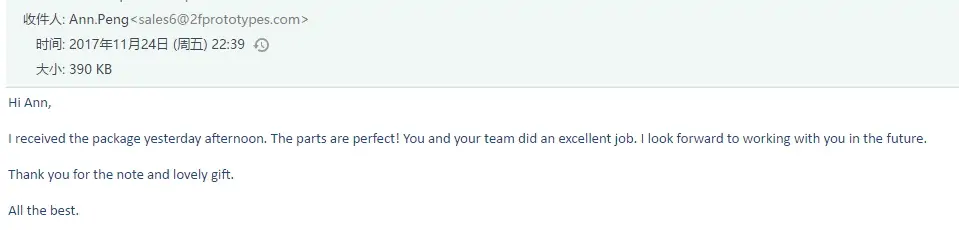

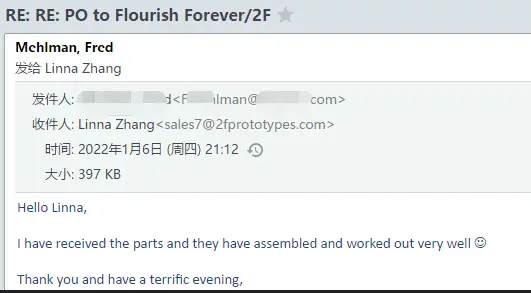

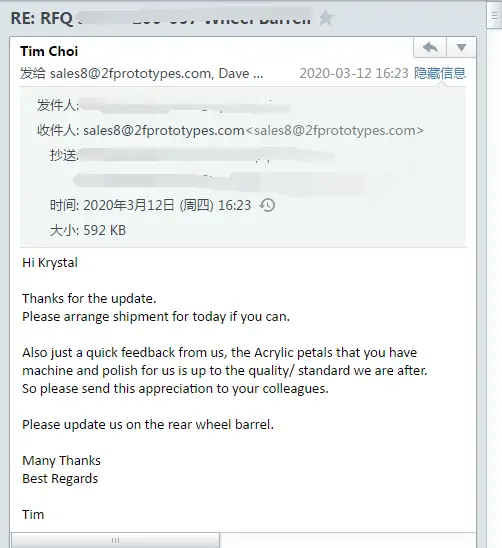

Hear directly from the companies we’ve served — real feedback that reflects

our commitment to quality, reliability, and trust.

Communicate your requirements with us and we will contact you as soon as possible