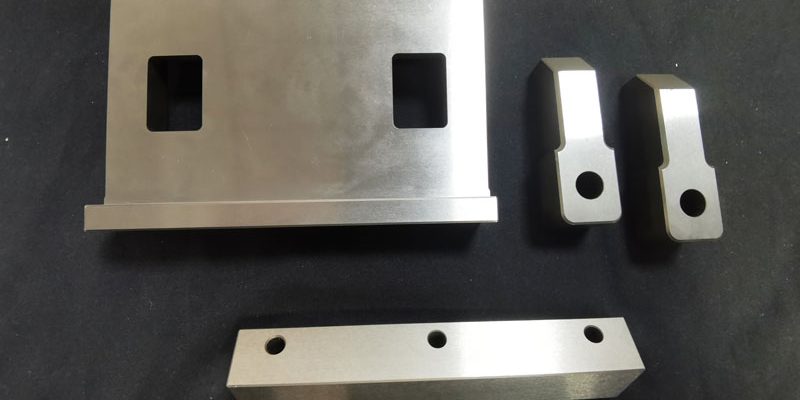

Stainless Steel Parts For Turning And Milling

Stainless steel has advantages in corrosion resistance and wear resistance, and stainless steel parts have high strength and toughness, and are widely used in mechanical equipment, molds and other fields. This stainless steel part is a key component of a certain mechanical equipment and requires high precision.

The difficulties in processing stainless steel parts mainly include the following aspects

1.This type of material has high strength, large tangential stress and large plastic deformation during cutting, so the cutting force is large. In addition, the thermal conductivity of the material is extremely poor, causing the cutting temperature to rise, and the high temperature is often concentrated in the narrow area near the cutting edge of the tool, thus accelerating the wear of the tool.

2.Austenitic stainless steel parts and some high-temperature alloy stainless steels have an austenitic structure. CNC work hardening tendency is large during cutting, usually several times that of ordinary carbon steel. The tool cuts in the machine hardened area, shortening the tool life. .

3.Both austenitic stainless steel parts and martensitic stainless steel parts have the characteristics of strong chips and high cutting temperature during processing. When strong chips flow through the rake face, adhesion, welding and other sticking phenomena will occur, affecting the surface roughness of precision machined parts.

4.The above-mentioned materials generally contain high-melting-point elements, have high plasticity, and have high cutting temperatures, which accelerate tool wear and require frequent tool sharpening and tool replacement, thus affecting production efficiency and increasing tool usage costs. 2F Prototypesis a machining factory with more than ten years of CNC manufacturingexperience. It has complete equipment, CNC turning/milling/grinding/drilling/processing. Partners with parts processing needs are welcome to call us for quotations.

Turning and milling of batch stainless steel parts

一. Turning processing

Turning is the most widely used type in the machine manufacturing industry. There are a large number of lathes, many people, a wide range of processing, and many tools and fixtures used. Therefore, the safety technical issues of turning are particularly special. Importantly, try to use it for batch processing. The key tasks are as follows:

1.Chip damage and protective measures. Various steel parts processed in batches on lathes have good toughness. The chips generated during turning are full of plastic curl and have sharp edges.

2.Installation of workpieces. In the process of turning batch processing, there are many accidents in which machine tools are damaged, tools are broken or crashed, and workpieces fall or fly out due to improper clamping of workpieces, causing injuries to people. Therefore, in order to ensure safe production during turning processing, special attention must be paid when mounting workpieces.

3.Safe operation. Before working, the machine tool must be fully inspected and confirmed to be in good condition before use. The workpiece and tool clamping ensure correct, firm and reliable position. During the machining process, the machine must stop when changing tools, loading and unloading workpieces, and measuring workpieces. , has long been committed to the processing of high-precision, highly difficult, and easily deformable metal and plastic parts, small and medium-sized batch production and manufacturing of lightweight alloy and composite material (such as aluminum alloy, carbon fiber, etc.) parts, and robot parts procurement and customization services.

二. Milling processing

CNC lathes can process complex rotary body shapes. Milling is to fix the blank and use a high-speed rotating milling cutter to cut out the required shapes and features. Traditional milling is mostly used for milling simple shapes/features such as contours and slots. CNC milling machines can process complex shapes and features. The milling and boring machining center can perform three-axis or multi-axis milling and boring processing, and is used for processing molds, inspection tools, molds, thin-walled complex curved surfaces, artificial prostheses, blades, etc. When selecting CNC milling processing content, the advantages and key role of CNC milling machines should be fully utilized.

A common metal cold working method. The difference from turning is that in milling, the tool rotates at high speed driven by the spindle, while the workpiece is relatively stationary.

The difference between turning and milling

Turning is used to process rotary parts. The parts are clamped on the machine tool spindle through a three-grip chuck and rotated at high speed. Then, a turning tool is used to cut along the busbar of the rotary body to cut out the product appearance. The lathe can also process inner holes, threads, engravings, etc., and the latter two are low-speed processing.