Professional Prototype Machining: A Comprehensive Guide from Concept to Realization

In today’s rapidly evolving manufacturing industry, the swift development and validation of product prototypes have become increasingly crucial. Prototype machining, a method that swiftly transforms design concepts into tangible models, has become an indispensable part of the product development process. This article delves into various aspects of professional prototype machining, including its definition, importance, machining techniques, material selection, and how to choose the right prototype machining service.

What is Professional Prototype Machining?

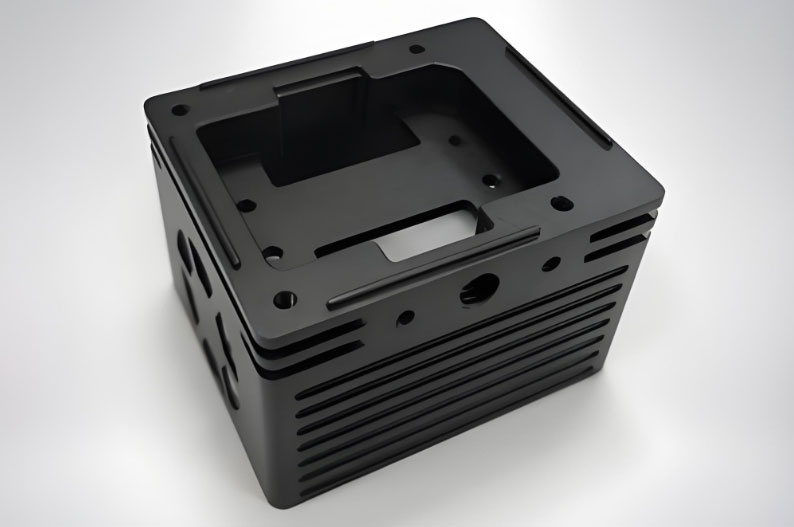

Professional prototype machining refers to the process of using specialized techniques and equipment to quickly create product prototypes based on design drawings or digital models. These prototypes are typically used for design verification, functional testing, market presentation, and attracting investment. Compared to traditional production methods, prototype machining offers advantages such as speed, relatively lower costs, and high flexibility.

Why Choose Professional Prototype Machining?

- Rapid Iteration: In the early stages of product development, designers need to quickly iterate design concepts. Prototype machining can provide physical models in a short time, accelerating this process.

- Design Verification: Prototypes allow designers to visually inspect the product’s dimensions, shape, and appearance to ensure the design meets expectations.

- Functional Testing: Prototypes can be used for preliminary functional tests such as assembly, disassembly, and durability.

- Market Feedback: Before launching a product, prototypes can be used for market research to gather feedback from potential users.

- Attracting Investment: A high-quality prototype can vividly showcase the product concept, helping attract investors or partners.

Prototype Machining Techniques

Various techniques are used in prototype machining, including but not limited to:

- CNC Machining: Uses computer numerical control machines to precisely process materials, suitable for complex shapes and high-precision requirements.

- 3D Printing: Rapidly builds materials layer by layer to form three-dimensional models, ideal for quick prototyping and design verification.

- Silicone Mold Replication: Suitable for small batch replication, quickly producing multiple identical prototypes.

- Laser Cutting: Uses laser technology to precisely cut materials, suitable for two-dimensional or simple three-dimensional structures.

- Hand Crafting: For special materials or highly customized prototypes, hand crafting is a good option.

Material Selection

Choosing the right materials is crucial for prototype machining. Common materials include:

- Plastic: Lightweight, easy to machine, suitable for most prototypes.

- Metal: High strength, suitable for prototypes that need to withstand significant force or high-temperature testing.

- Wood: Natural texture, suitable for displaying the appearance and feel of the product.

- Resin: Can create smooth surfaces, suitable for finely detailed prototypes.

- Composite Materials: Combine the advantages of various materials, suitable for prototypes with special requirements.

How to Choose the Right Prototype Machining Service?

When selecting a prototype machining service, consider the following factors:

- Technical Capability: Ensure the service provider has the necessary technology and equipment to realize your design.

- Material Availability: Confirm that they can provide the types of materials you need.

- Quality Control: Understand their quality control processes to ensure the prototype meets your standards.

- Delivery Time: Choose a service provider that can meet your timeline requirements based on your project schedule.

- Cost: Compare prices from different service providers to choose the one with the best cost-performance ratio while ensuring quality.

Conclusion

Professional prototype machining is a critical step in the product development process, helping designers and manufacturers quickly validate designs, shorten time to market, and reduce development costs. Selecting the right prototype machining techniques and service providers ensures that your product prototypes accurately reflect the design intentions swiftly and accurately, laying a solid foundation for the success of the final product.