Plastic injection molding - Mass producion capabilities

Plastic Injection Molding Service

Plastic injection molding is designed especially for the mass production of plastic parts by repeatedly using the same mold. Consistent color, structure, appearance is the features for injection molded parts. Hundreds of thousands of custom parts are produced by machines. The cost of per part decrease with higher quantity manufacturing runs.

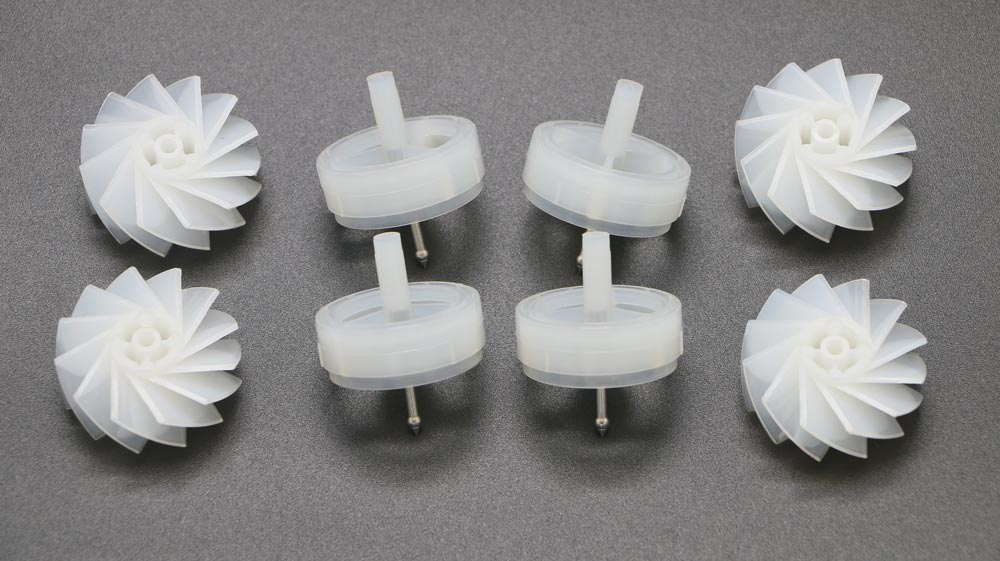

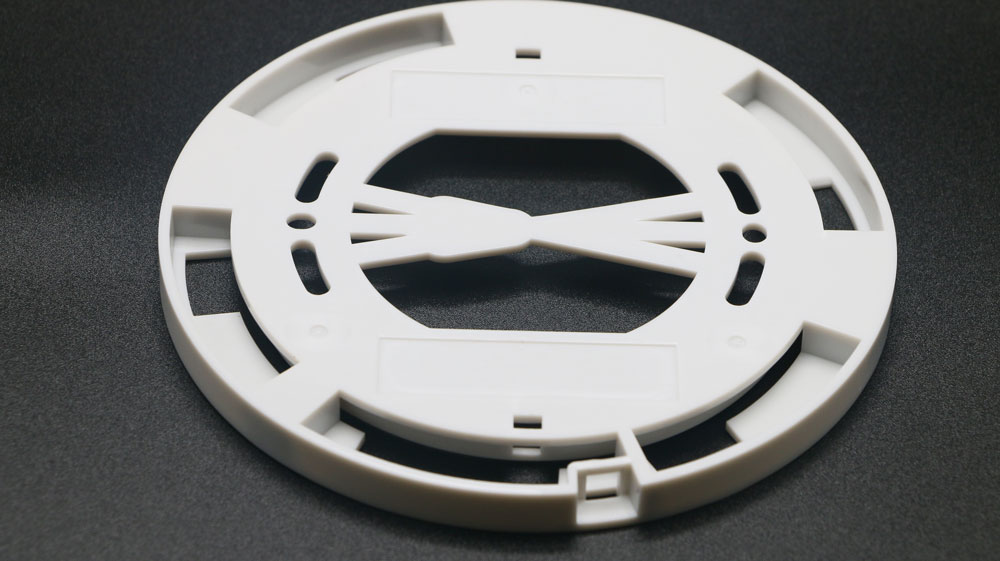

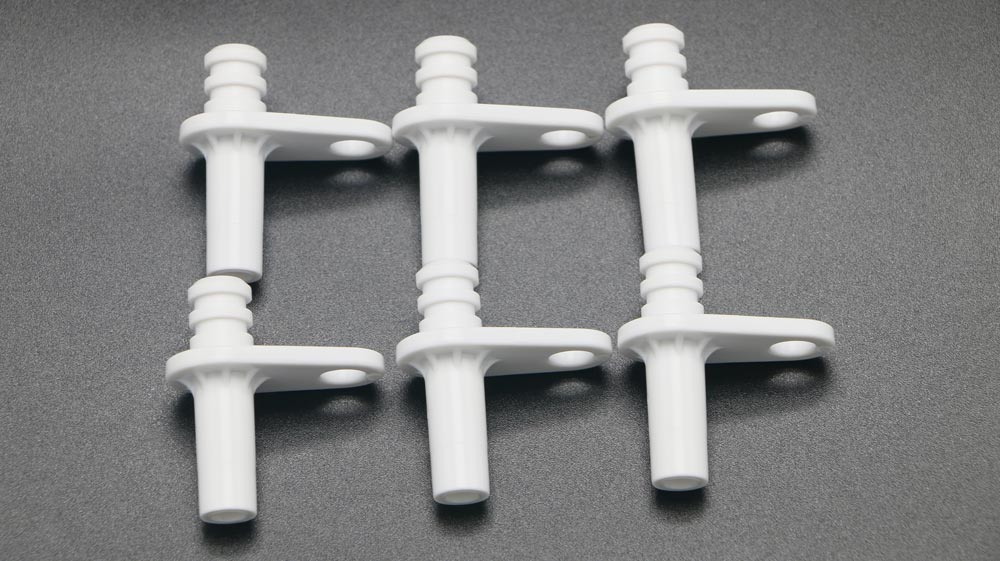

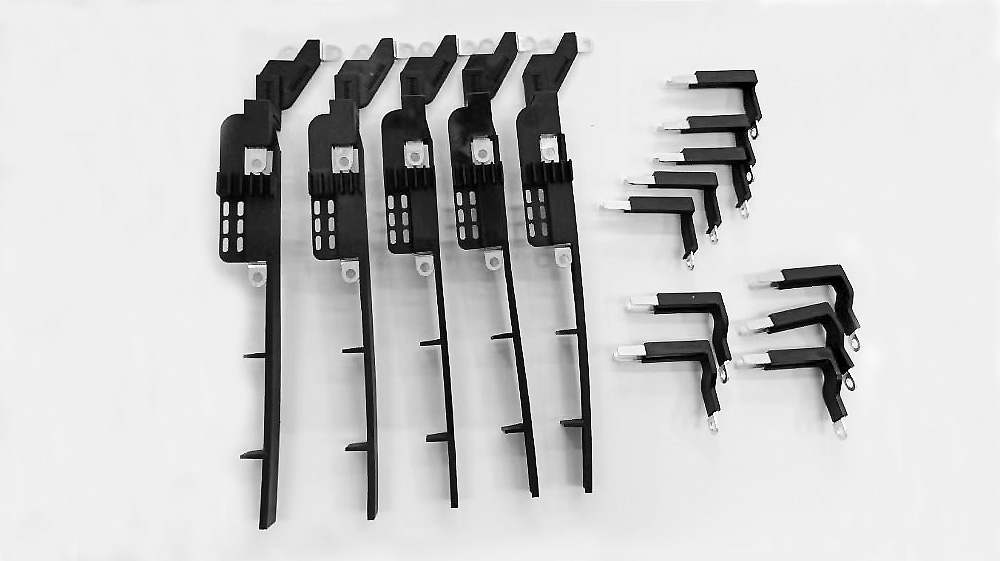

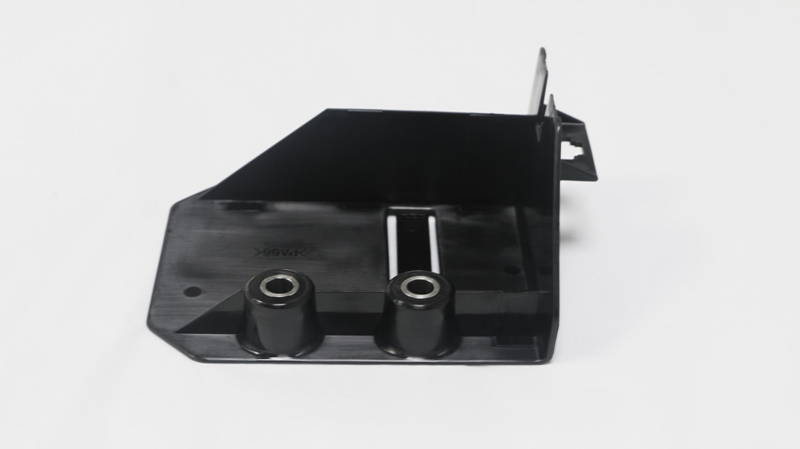

Finished Product Gallery

2f prototypes’ customers come from all walks of life around the world. The processed products cover the medical equipment industry, auto parts industry, aviation and shipping industry, industrial machinery manufacturing, electronic and electrical manufacturing, fitness equipment industry, etc.

Our Capabilities

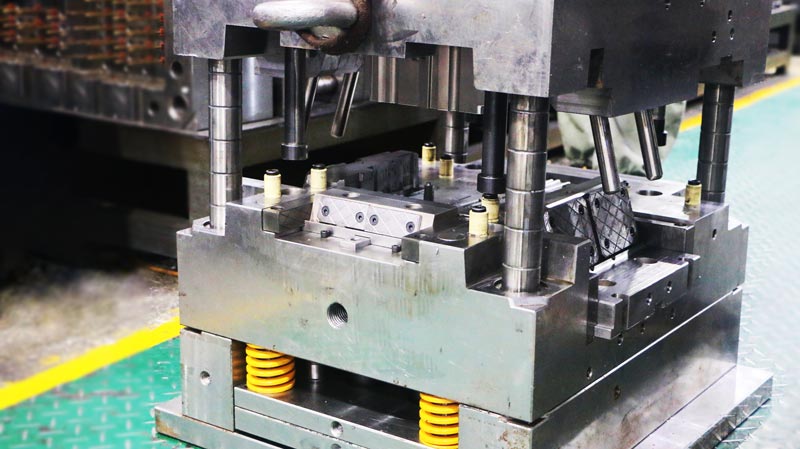

2fprototypes have 30+ injection molding machines from 80T to 1600T in factory of 3500 square meter that can produce common size injection molded parts. The tonnage calculation/clamping force is one of the key factors for quality and cost. It keeps the tooling closed during the injection process. The higher tonnage, the higher weight of tooling it can keep.

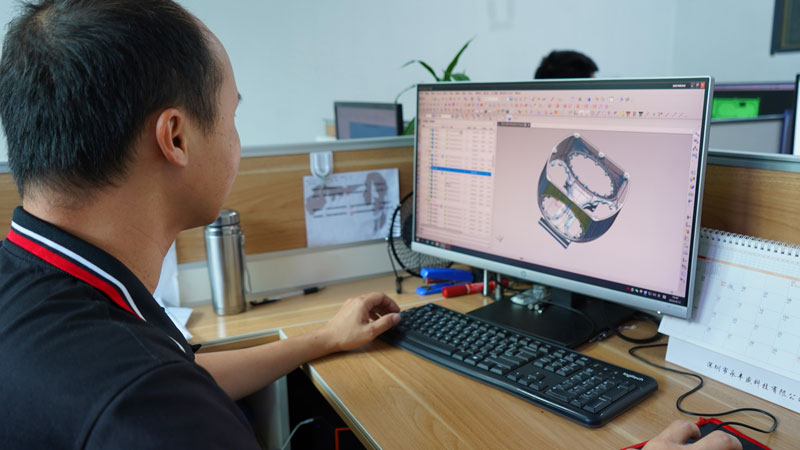

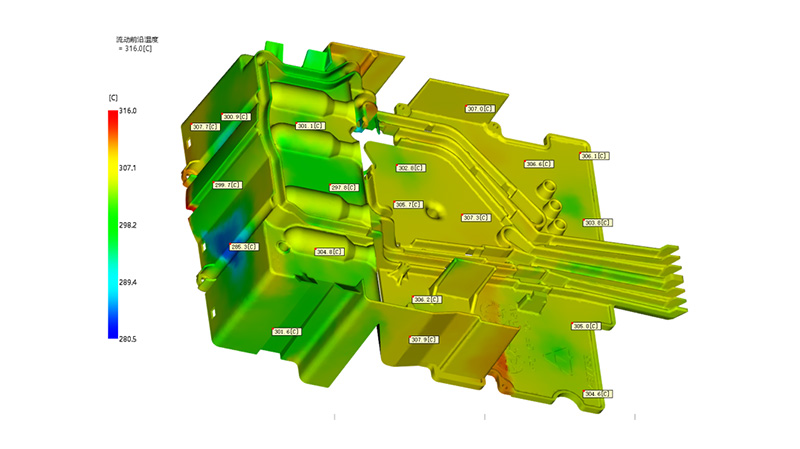

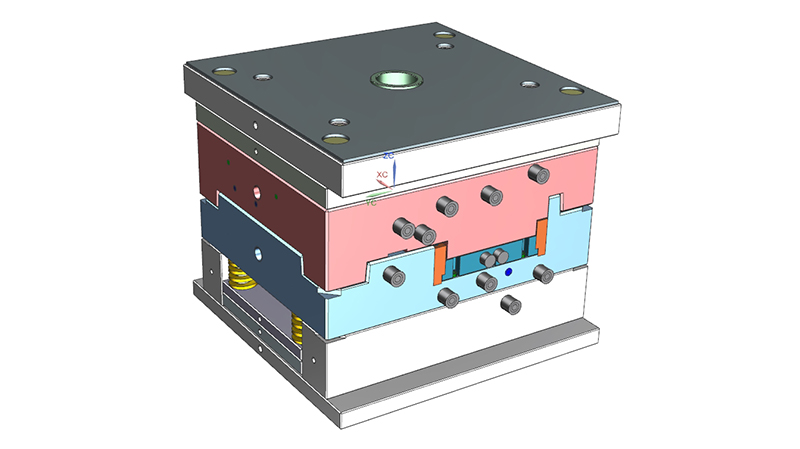

Production Process

From making prototypes to opening molds to mass production, 2fprototyps receives hundreds of orders from all over the world every day for production. 2fprototyps has no MOQ limit and accepts any quantity of production scale. 2fprototyps provides one-stop service for materials, processing, post-processing, home delivery, etc. You only need to provide us with 3D drawings, which will save you a lot of time to do other things.

Plastic Material list

2fprototypes provides various materials for our customers’ choice.

Polystyrene/PS and modified polystyrene/HIPS

- Good fluidity for easier processing;

- Good dimensional stability; Easier coloring;

- High brittleness for poor shock resistance;

- Can be scratched on the surface easily;

- Poor acid resistance for crazing;

polymethyl methacrylate/PMMA/Acrylic

- Burning slowly;

- High transparency;

- Forming easily;

- Scratching easily

Propylene - butadiene - styrene polymers/ABS

- The best electroplate ability among plastics;

- The ingredient of butadiene improve the shock resistance greatly;

- Good surface gloss;

- Low shrinkage for reliable dimension;

- Organic solvent intolerance, can be dissolved into emulsion when combining with ketone, ester, aldehyde, and chlorinated hydrocarbon

Polyamide/PA/Nylon - Crystalline plastics

- Good toughness;

- Good wear resistance;

- Good fatigue resistance;

- Good self-lubrication;

- Good self-extinguishment;

- Good strength of extension;

- High water absorption

Polyformaldehyde/POM - Crystalline plastics

- Comprehensive mechanical performance;

- High rigidity and hardness; Excellent worn resistance and self-lubrication;

- Organic solvent tolerance;

- Low moisture that can maintain stable dimension;

- Low acid resistance;

- Low adhesiveness;

Polycarbonate/PC - Crystalline plastics

- The best plastic of shock resistance; Low forming shrinkage(0.05-0.7%) that the end-part is precise and the dimension is stable;

- Burning slowly;

- Can be dissolved in organic solvent such as alkali, ketone, aromatic hydrocarbon, etc.

- Poor fatigue resistance;

- Significant ESCR;

Polyethylene/PE - Crystalline plastics

- Usually used for blow molding products;

Its chemical properties are reliable that can’t be dissolved into any solvent under room temperature; - Good toughness and extensibility even at low temperature;

- Poor mechanical strength;

- Low adhesiveness;

- Scratch on the surface easily;

Polyvinyl chloride/PVC

- It is soluble in cyclohexanone and dichloroethane;

- The softness of range can be extended after plasticizer is added;

- Good fire resistance;

- High shrinkage of soft PVC(1-2.5%);

- The PVC molecule absorbs water easily so that it needs to be dry before forming;

Polypropylene/PP - Crystalline plastics

- Lightweight;

- High tensile strength;

- Good formability;

- Good wear resistance;

- Shock resistance under room temperature;

- High forming shrinkage(1.6%) that plastic part can be deformed and shrink easily;

- Low adhesiveness;

Surface Finish List

⭐ Spray painting

⭐ Silk-screen

⭐ Transfer-printing

⭐ Electroplating

⭐ Laser etching

⭐ Anodizing

⭐ Scouring/brushing

⭐ High glaze

⭐ UV-finish

⭐ Embossing

⭐ Polishing

⭐ Cleaning

⭐ Bake finish

⭐ Fuming PC

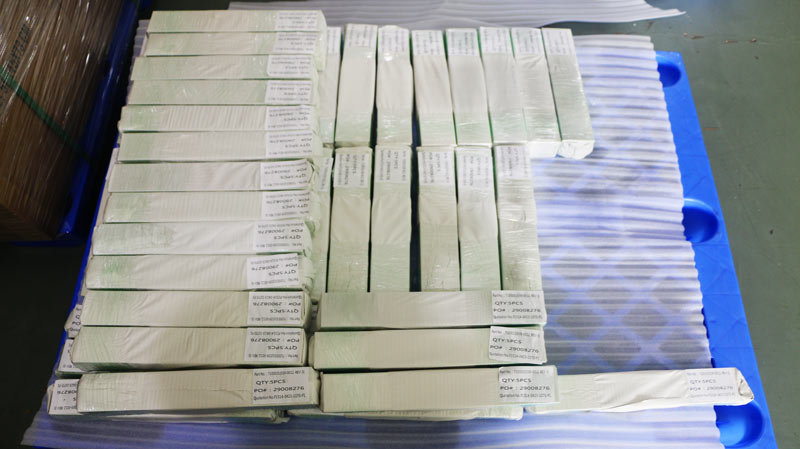

Packing & Delivery

Each finished plastic part will be well-packed with carton or wooden box, also you could tell us in advance if you have special requirements on your products’ package. 2f prototypes team could design custom external packing for customers.

Try 2fprototypes Now

All information will be secured and confidential