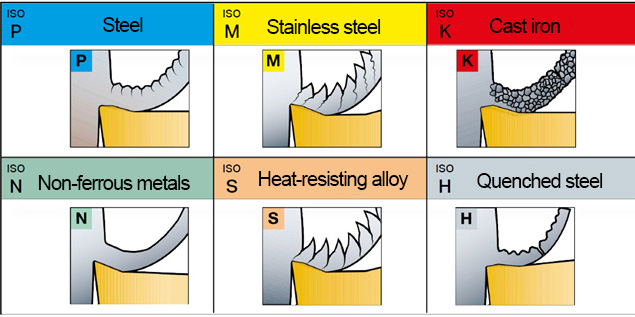

In metal cutting, there will be different workpiece materials, and different materials have different cutting formation and removal characteristics. How can we grasp the characteristics of different materials? ISO standard metal materials are divided into 6 different types of groups, each Each type has unique characteristics in terms of machinability, and this article will classify

Don’t summarize them.

Metal materials are divided into 6 categories:

(1) P-Steel

(2) H-hardened steel

(3) M-stainless steel

(4) S-Heat Resistant Metal

(5) N-Non-ferrous metals

(6) K-Cast iron

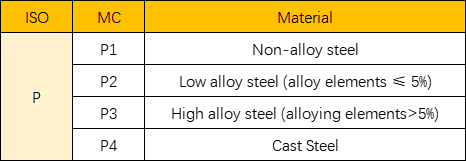

- -P Steel

What is steel?

– Steel is a very common group of materials in the field of metal cutting.

– Steel can be non-hardened steel or quenched and tempered steel (hardness up to 400HB).

-Steel is an alloy mainly composed of iron (Fe) element. It is manufactured through a smelting process.

– Unalloyed steels have a carbon content below 0.8% and have only Fe and no other alloying elements.

– The carbon content of alloy steel is less than 1.7%, and alloying elements are added, such as Ni, Cr. Mo, V, W, etc.

Fields of application: Within the metal cutting range, group P is a very common material group as it covers several different industrial sectors.

The material is usually a long chipping material, capable of forming a continuous, relatively uniform chip. The specific chip form usually depends on the carbon content.

– Low carbon content = tough sticky material.

– High carbon content = brittle material.

Machining characteristics: – Long chipping materials.

– Chip control is relatively easy and smooth.

– Mild steel is sticky and requires a sharp cutting edge.

-Unit cutting force kc: 1500~3100 N/mm²

– The cutting force and power required for adding IISO P materials are within the limited range.

- -H Hardened steel

What is hardened steel?

– Hardened steels are the smallest grouping from a machining point of view.

– This group contains quenched and tempered steels with hardness > 45~65 HRC.

-Usually, the hardness of the hard parts being turned is generally in the range of 55~68 HRC.

Fields of application: Hardened steels in group H are used in various industries, such as the automotive industry and its subcontractors, as well as machine building and mold business.

Chip shape: Usually continuous, red-hot chips. This high temperature helps lower the kc1 value, which is important to help solve application challenges.

Processing characteristics:

– Long chipping materials.

– Relatively good chip control.

-Negative rake angle is required.

-Unit cutting force: 2550~4870 N/mm²

– High cutting forces and power required.

- -M Stainless steel

What is stainless steel?

-Stainless steel is an alloy material with a minimum of 11%~12% chromium.

– Carbon content is usually very low (as low as **0.01%)

– The alloys are mainly Ni (nickel), Mo (molybdenum) and Ti (titanium).

– Forms on the steel surface – a dense layer of Cr203, making it corrosion resistant.

Fields of application: In Group M, the majority of applications fall under the oil and gas, pipe fittings, flanges, process industries, and pharmaceutical industries.

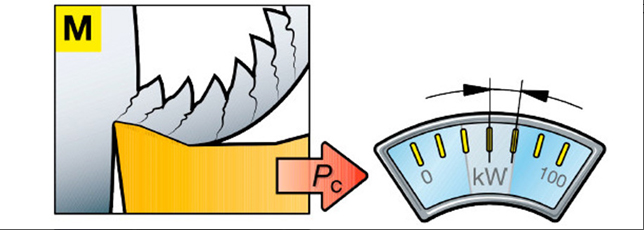

Chip shape: The material forms irregular, flake-like chips that are more forceful than ordinary steel. There are many different types of stainless steel. Chip breaking performance (from easy to almost impossible chip breaking) varies with alloy properties and heat treatment.

Processing characteristics:

– Long chipping materials.

– Chip control is relatively smooth in ferritic and difficult in austenitic and duplex.

-Unit cutting force: 1800~2850 N/mm²

– High cutting forces, built-up edge, heat and work hardening during machining.

- -S Heat-resistant alloy

What are Heat Resistant Alloys?

Heat resistant alloys (HRSA) include many high alloy iron, nickel, cobalt or titanium based materials. Group: Iron-based, Nickel-based, Cobalt-based

Conditions: Annealing, solution heat treatment, aging treatment, rolling, forging, casting.

Features: Higher alloy content (cobalt higher than nickel) ensures better heat resistance, higher tensile strength and higher corrosion resistance.

Applications: Difficult-to-process S-group materials are mainly used in the aerospace, gas turbine and generator industries.

Wide range, but usually high cutting forces.

Processing characteristics:

– Long chipping materials.

Chip control is difficult (jagged chips).

– A negative rake angle is required for ceramics and a positive rake angle is required for carbide.

-Unit cutting force: for heat-resistant alloy: 2400~3100 N/mm²; for titanium alloy: 1300~1400 N/mm²

The cutting forces and power required are high.

- -N Non-ferrous metals

What are non-ferrous metal materials?

This category includes non-ferrous metals, soft metals with a hardness below 130 HB.

-Non-ferrous (AI) alloys containing nearly 22% silicon (Si) make up the largest portion of them.

– Copper, bronze, brass.

Fields of application: aircraft manufacturing and aluminum alloy automobile wheel manufacturers occupy a dominant position in Group N.

Although the power required per cubic inch is low, it is still necessary to calculate the maximum power required to obtain a high metal removal rate.

Processing characteristics:

– Long chipping materials.

– Chip control is relatively easy if it is an alloy.

– Non-ferrous metals (AI) are sticky and require sharp cutting edges.

-Unit cutting force: 350~700 N/mm²

– The cutting force and power required to process ISO N materials are within the limited range.

- -K Cast iron

What is Cast Iron?

– There are 3 main types of cast iron: Gray Iron (GCI), Ductile Iron (NCI) and Compacted Graphite Iron (CGI).

-Cast iron is mainly composed of Fe-C, with a relatively high silicon content (1%~3%).

– The carbon content exceeds 2%, which is the only solubility of C in the austenitic phase.

-Cr (chromium), Mo (molybdenum) and V (vanadium) are added to form carbides, increasing strength and hardness, but reducing machinability.

Fields of application: Group K is mainly used in automotive components, machine building and ironmaking.

Cutting Eyebrow Shape: The chip shape of the material varies, from approximately powdery chips to long chips. The power required to process this material group is generally small. *Note: There is a big difference between gray cast iron (which usually has chippings that are close to powder) and ductile iron, where chip breaking is often more similar to steel.

Processing characteristics:

– Short chipping material.

-Good chip control in all conditions.

-Unit cutting force: 790~1350 N/mm²

– Machining at higher speeds produces abrasive wear.

– Medium cutting force.