China’s Domestic Mold and Injection Molding Industry (Part 1)

-

Overview of the Plastic Products Industry

Plastic products are materials made from synthetic or natural high molecular compounds, using plasticizers, fillers, lubricants, injection molding agents, and other additives as auxiliary components. These materials, consisting of plastic and small amounts of solid substances, are produced under specific temperature and pressure conditions. Plastics, known for their lightweight, strong plasticity, low manufacturing costs, and wide range of applications, have gained extensive use in modern society.

Currently, synthetic high molecular materials have become indispensable new materials for humanity, constituting one of the four major foundational materials in modern society alongside steel, wood, and cement. They play a crucial role in supporting the development of modern society and are widely applied in information, energy, industry, agriculture, transportation, and other sectors of the national economy. In recent years, China’s plastic products industry has experienced rapid development, continuously expanding in scale, and becoming an essential component of the national economy.

In 2013, China’s plastic product output reached 61.89 million tons, with a year-on-year growth of 8.02%. As of December 2014, there were 14,062 enterprises in the plastic products industry with a scale above a certain threshold. These enterprises achieved a main business income of CNY 2,039.24 billion, a year-on-year growth of 8.92%, and a total profit of CNY 118.29 billion, a growth of 4.24%. The export delivery value reached CNY 226.07 billion, marking a 2.82% increase. It is evident that the industrial scale of the plastic products industry in China is expanding continuously, with annual output increasing, although the growth rate has slowed down in the past two years.

Looking into the subdivisions of the plastic products industry, plastic pipes and fittings, plastic filaments, and woven products in plastic packaging are widely used categories. Plastic films and plastic packaging containers follow, with daily plastic products and plastic parts manufacturing coming next.

Among them, the main business income and export delivery value of the plastic parts manufacturing industry have shown an upward trend in the past five years. Between 2010 and 2011, the growth was particularly rapid, with main business income increasing from CNY 237.28 billion to CNY 709.56 billion, nearly a 200% growth, and export delivery value increasing from CNY 63.58 billion to CNY 191.43 billion. Although the growth rate slowed down from 2012 to 2014, the main business income continued to expand, reaching CNY 939.41 billion by the end of 2014.

-

Overview of the Mold Manufacturing Industry

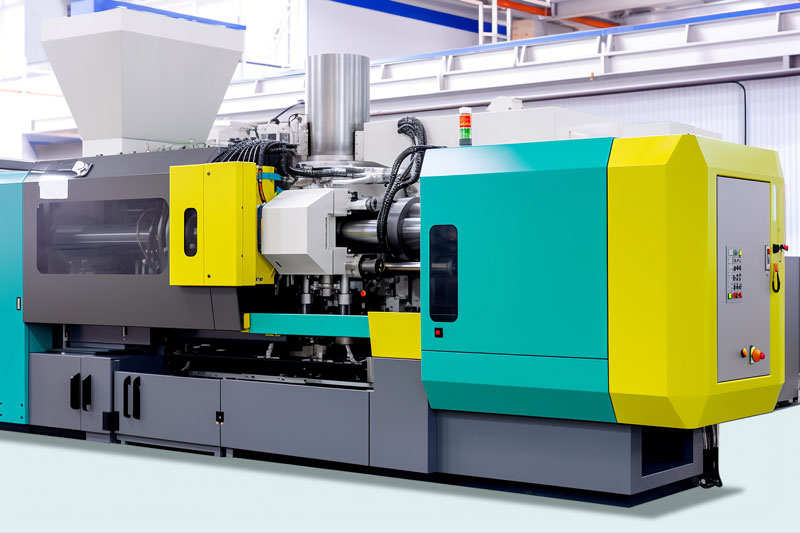

Molds are basic process equipment processed from materials such as plastic, rubber, metal, powder, glass, and fiberglass. They are intermediate products in the production process, used for the production of final products. Mold processing is an important method of material shaping, possessing advantages such as fewer processes, high material utilization, low energy consumption, easy production, and high efficiency compared to mechanical processing. Therefore, molds are widely used in the production of automobiles, energy, machinery, electronics, information, aerospace industries, and daily necessities.

Statistics show that 75% of rough machining industrial product parts and 50% of precision machining parts are formed by molds. In the household appliance industry, more than 80% of parts, and in the electromechanical industry, over 70% of parts need mold processing. The mold industry often drives the development of related industries, earning it the nickname “efficiency amplifier.”

Although China’s mold industry started early, it initially operated as an affiliated enterprise of downstream production companies. The circulation rate of mold products was low, limiting the development of mold enterprises. It was not until 1987 that molds were officially listed as products in the electromechanical product catalog. At that time, there were approximately 6,000 mold-producing factories nationwide, with a total output value of around CNY 3 billion. After more than 20 years of development, China’s mold industry has made significant progress. By 2013, there were 30,000 enterprises, and the annual output value reached CNY 220 billion, with an export value close to USD 5 billion.

Currently, the largest markets for China’s mold industry are the automotive industry, electronic information industry, home appliances and office equipment, machinery, and building materials industry. With the rapid development of China’s national economy and the increasing income levels of the people, the demand for automobiles, electronic consumer products, home appliances, and the like has continuously grown. This has led to these industries entering a high-speed development stage, becoming a significant factor in the rapid development of China’s mold industry. According to statistics, in recent years, the output value of China’s mold industry has grown rapidly, increasing from CNY 87 billion in 2007 to CNY 210.6 billion in 2013, with a growth rate far exceeding the overall level of the world mold industry.