CNC machining is the most important process method for making prototype models in nowadays. The diversification of prototype processing methods has not changed the position of CNC in the process of prototype production.

CNC prototypes generally match large-scale prototypes with high precision requirements and high appearance requirements.

Why do we often choose CNC machining prototypes? Today, 2fprototypes will analyze the characteristics of the CNC prototype from the processing materials, application fields, and advantages of the CNC prototype.

1.The CNC prototype model can process a wide range of materials, and the processable materials include ABS, POM, PC, acrylic ( or PPMA,a transparent material), stainless steel, aluminum alloy, H62 brass, Q235 iron, etc.

The following are some common materials, let’s learn about their physical properties and application scope:

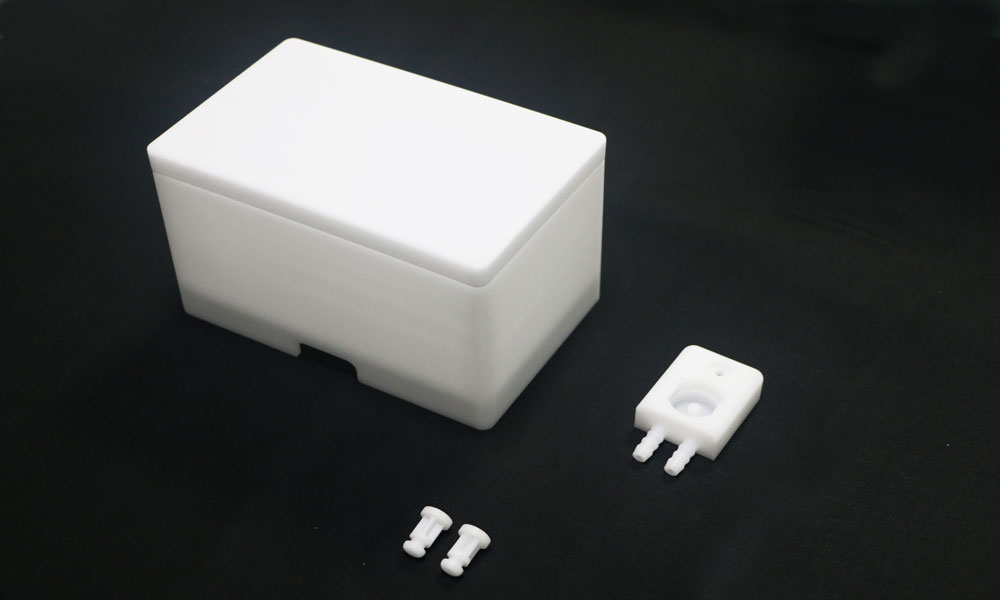

(1). ABS prototype

Temperature resistance: 60-80℃

Features: Excellent strength and durability

This material is mostly used for prototypes such as electrical appliances, medical care, and cars.

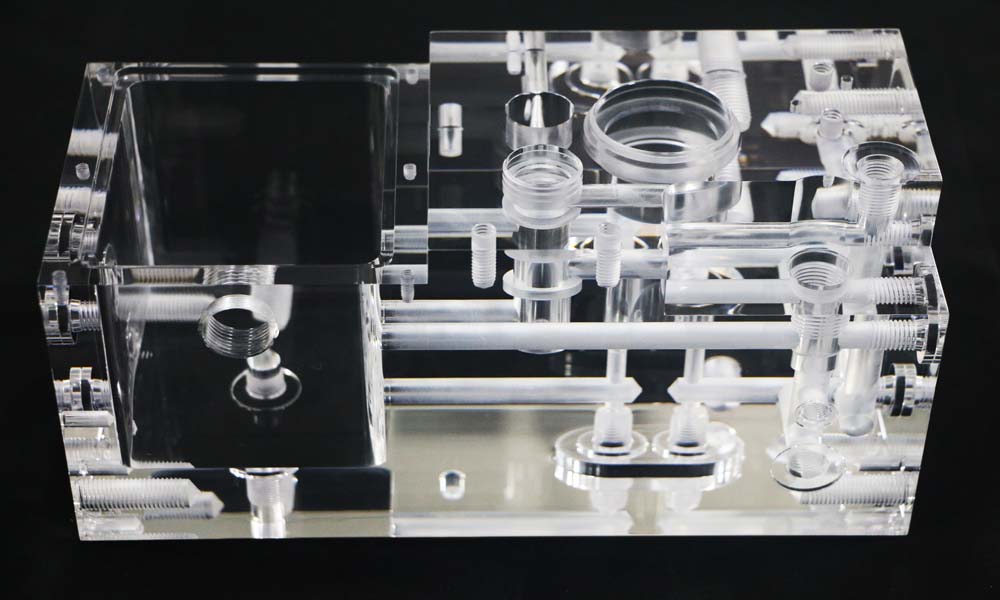

(2).PMMA acrylic hand board

Temperature resistance: 60-80℃

Features: high transparency

Mostly used in electrical liquid crystal shell prototypes

(3).POM race steel prototype

Temperature resistance: 90-110℃

Features: good strength, durability, hardness

Scope of application: mechanical gears, rotating parts prototypes

(4).For the physical property analysis of other materials, you can consult our engineer Mrs Chen info@2fprototypes.com.

2.CNC prototype processing has a wide range of applications:

CNC prototype processing is often used in prototypes for cars, robots, medical, aerospace, design, small household appliances and computer peripheral products, and can also produce functional test standard parts for large complex products, such as air conditioners, monitors, audio, medical equipment, motorcycles, car accessories and other products.

3.CNC prototype model also has many advantages

(1).The CNC prototype model has a moderate cost, a wide range of processing materials and a wide range of applications, which can meet the requirements of different customers for strength, temperature resistance, durability, transparency, etc.

(2).The surface treatment methods of CNC hand model are diversified,

Such as grinding, ash spraying, painting, polishing, silk screen printing, electroplating, oxidation, laser engraving, bluing, UV, etc., the effect can even be more beautiful than the products produced by the mold.

(3).In terms of appearance, assembly, and functional verification, it can achieve the purpose of customer planning and verification, and CNC can make a workpiece that can truly reflect your planning purposes.

Due to its many advantages, CNC prototyping has always been the mainstream processing method of modern prototyping. It is not only suitable for various fields, but also allows customers to achieve the best results for verification purposes.

One Reply to “CNC machining is the most important process method for making prototype models in 2022”

不知道说啥,开心快乐每一天吧!