How to improve the precision of CNC lathe processing

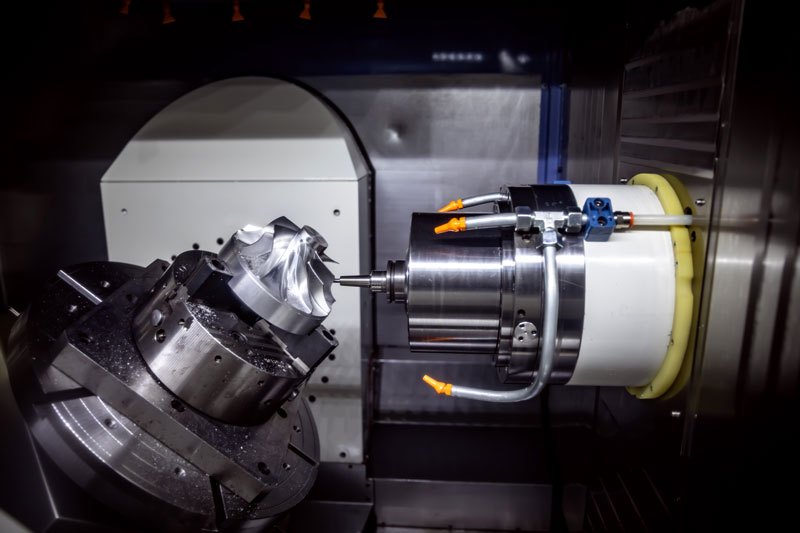

The emergence of CNC lathes is a major advancement in the industry. It can better solve the processing problems of complex, precise, small batches and changeable parts. It is a flexible and efficient automatic machine tool. When machining with a CNC machine, a process analysis must first be performed. According to the material, contour shape and machining accuracy of the workpiece to be machined, select the appropriate machine tool, formulate a machining plan, determine the machining sequence of the parts, and use cutting tools, fixtures and cutting oils. Identify each process. The following points are briefly introduced to improve the process of CNC lathe machining accuracy.

1.Reasonable selection of cutting parameters

For efficient metal cutting, the material to be machined, the cutting tool, and the cutting conditions are the three major elements. These determine the machining time, tool life and machining quality, and a cost-effective machining method is bound to be a reasonable choice for cutting conditions.

Three factors of cutting conditions: cutting speed, feed rate and depth of cut directly lead to tool damage. The choice of tool life is related to tool wear, dimensional changes, surface quality, cutting noise and machining heat.

The relationship between feed conditions and tool rear wear occurs within a very small range. However, the feed rate is high, the cutting temperature increases, and the rear wear is large. It affects the cutting tool less than the cutting speed. Depth of cut does not affect the cutting tool as much as cutting speed and feed, but the hardened layer produced by the cutting material can also affect tool life in micro-cutting.

2.Reasonable selection of tools.

(1) When rough turning, a cutting tool with high strength and good durability should be selected to meet the requirements of large feed and large feed during rough turning.

(2) Choose accurate and durable tools to ensure machining accuracy.

(3) In order to reduce tool change time and facilitate tool change, clamps and blades should be used as much as possible.

3.The correct choice of lamps.

(1) Try to use general fixtures to clamp the workpiece and avoid using special fixtures.

(2) The positioning datum of the parts is coincident to reduce the positioning error.

4. Determine the processing path.

The machining path is the motion path and direction of the tool relative to the part during the machining process of the index-controlled machine tool.

(1) The machining accuracy and surface roughness should be guaranteed.

(2) The processing route should be shortened to reduce the idling time of the tool.

5.The relationship between the machining path and machining allowance.

In general, excess parts from a blank, especially those containing forged and cast hard skins, should be machined on an ordinary lathe. If a CNC lathe is required, attention should be paid to the flexible arrangement of the program.

7.Use special cutting oil.

In general, for easier cleaning of the finished product, a better viscosity should be determined based on processing difficulty and degreasing conditions. Some workpiece raw materials will react with chlorine additives, so pay attention to white rust when selecting cutting oils. Cutting oils with sulphur and chlorine compound additives ensure extreme pressure machining performance and avoid burrs and cracks on the workpiece.

The above are the matters needing attention in the ordinary cutting process. Through the continuous improvement process, the reasonable selection of cutting tools and cutting oil can effectively improve the cutting accuracy.

For CNC machining services, please consult 2fprototypes – a professional CNC machining rapid prototyping supplier.