Discussion on the difference between injection molding and CNC machining

There are many ways to make plastic parts when designing and producing them. Before you start making parts, it’s important to find the right way to process them. Today we’re going to talk about plastic injection molding and CNC machining.

What is injection molding?

Plastic injection molding produces parts by injecting a molten material, most commonly thermoplastic, into a mold. Prior to injection, the plastic is heated in a barrel, injected into a mold, moved along a channel called a runner, and then into the part itself. When this is done, the mold is opened and the part is ejected, ready to begin the process again. Precision parts can be produced very quickly with suitable plastic resins.

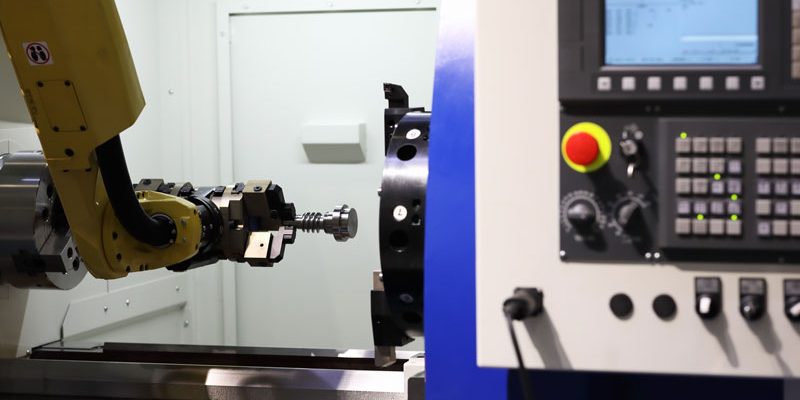

What is CNC machining?

CNC – stands for Computer Numerical Control – Machining refers to the use of computer controlled removal of a layer of material from a solid block. This information is extracted from CAD or similar digital files, allowing files to be changed between production. The computer breaks these files down into a series of commands that are fed to one or more milling tools that process the material to produce the final product. This allows for quick transitions between digital designs and physical parts.

Injection molding and CNC machining:

The comparison of the two processes is similar to many of the comparisons between injection molding and other processes, which have higher lead times and costs, but both outperform CNC machining in terms of volume and cost once top speed is reached.

Potential costs: CNC machining requires creating CAD files and converting them to be used in the factory. Injection molding requires the creation of molds, which requires a lot of time and money.

Volume: In terms of unit price, injection molding wins in terms of volume. Although CNC milling is cheaper for hundreds or hundreds of parts.

Materials: Injection molding covered plastics, especially thermoplastic and thermosetting resins, cover everyday plastics from ABS to nylon. CNC machining Due to the milling process, softer materials will be affected.