The one of most commonly used metal material for CNC machining – Aluminum

-

Do you know how attractive aluminum is?

-

Do you know why aluminum is the material favored by engineers in various industries?

-

Do you know why aluminum is the most common metal material for CNC machining?

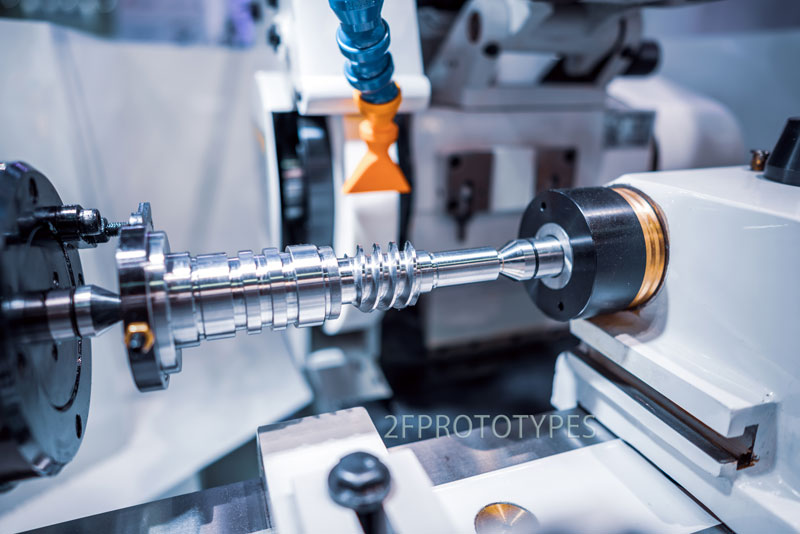

Let’s take a look at the explanation of aluminum by engineer Charles of 2fprototypes, a leading CNC machining and manufacturing industry in China:

Pure aluminum has low density, low melting point, high plastic deformation, easy processing, and can be made into various aluminum profiles and plates. Pure aluminum is added with other metal materials to obtain aluminum alloy, which has the characteristics of low density, high compressive strength and strong corrosion resistance.

The biggest feature of aluminum alloy is lightness and compressive strength. The aluminum used for CNC machining is aluminum alloy, which is widely used in the processing and manufacturing of various CNC parts.

At the beginning of the 20th century, aluminum alloy was born at the end of the century, and in the middle of the 20th century, CNC machine tools were born. After about 70 years of development, the CNC machining process of aluminum products has now entered the era of high-precision machining. The processing of aluminum products has gradually become the most common type of rare metal structural raw materials used in industrial production, and has been used in large quantities in aerospace, automobiles, machinery and equipment manufacturing, ships and chemicals.

The wide use of aluminum alloys has promoted the development trend of aluminum alloy CNC machining technology. At the same time, the development of CNC machining technology has expanded the use of aluminum alloys. Therefore, the CNC machining technology of aluminum alloys has become a scientific research hotspot.

Aluminum alloy can be divided into 6 series according to the series, 1 series, 2 series, 3 series, 5 series, 6 series, 7 series.

| Series | Specifications | Applications |

| 1 series | 1050、1060、1100、1145、1199、1350 etc. | Mainly used in food industry or packaging industry |

| 2 series | 2011、2014、2017、2024、2036、2048、2124、2218、2219、2319、2618、2A01、2A02、2A06、2A10、2A11、2A12、2A14、2A16、2A17、2A50、2A60、2A70、2A80、2A90 etc. | Mainly used in high-speed rail or aviation components |

| 3 series | 3003、3004、3105etc. | Mainly used in the packaging industry or in the construction field. |

| 5 series | 5005、5050、5052、5056、5083、5086、5154、5182、5252、5254、5356、5454、5456、5457、5652、5657、5A02、5A03、5A05、5A06 etc. | Mainly used in ships, pressure vessels, etc., as well as high-strength welded structures, such as marine pipelines, aircraft skeletons, etc. |

| 6 series | 6005、6010、6061、6063、6066、6070、6101、6151、6201、6205、6262、6463、6A02 etc. | Mainly used in industrial frame structures with high load-carrying capacity |

| 7 series | 7005、7039、7049、7050、7072、7075、7175、7178、7475、7A04 etc. | Mainly used in aerospace field, with high strength and bearing capacity. |

For customers choosing aluminum to make prototype boards, its advantages are:

The precision of CNC machining can be controlled

Nominal to High Tolerance

Short production cycle

Quantity increases and prices are economical

medium complexity

Various sizes can be processed

As a manufacturer with 12 years experience in CNC machining – 2fprototypes has up to 60 aluminum models for customers choosing to make prototypes. 2fprototypes is committed to making every client’s design concept to reality perfectly.

Want to get a quote for your project? Click here to get it now.