What is mill-turn machining?

Turning and milling combined processing can be referred to as turning and milling or turning and milling. Turn-milling is an advanced cutting process that uses the combined rotational motion of the milling cutter and the workpiece to cut the workpiece so that the workpiece meets customer requirements. Such as shape accuracy, position accuracy and integrity of machined surfaces. Turning and milling combined processing is not a simple combination of turning and milling on a machine tool, but uses simultaneous or continuous motion of turning and milling to process various surfaces. With turn-mill services, customers can obtain high-precision and complex-shaped prototypes in a very short time and at a low cost. This kind of composite processing can also be applied to high-volume production.

Why is turning and milling helpful?

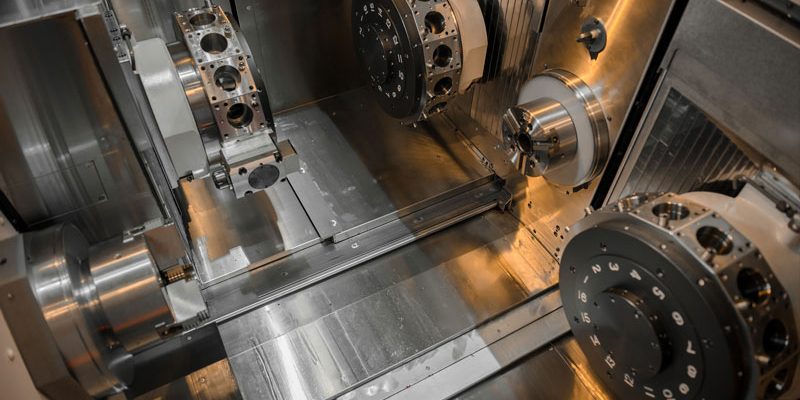

Usually, turning and milling are performed by turning and milling CNC machines. Turning and milling compound CNC machine tools are one of the main types of combined machine tools. Generally, many milling processes can be realized on the basis of CNC lathes, such as milling, drilling, tapping and slot milling. This turning and milling compound CNC machine tool has turning, milling and boring functions.

Composite function, one complete processing can be achieved with one clamping.

What is a turning and milling machine?

The movement of the turn-milling machine includes four basic movements: milling cutter rotation, workpiece rotation, milling axial feed and radial feed. According to the relative position of the workpiece rotation axis and the tool rotation axis, turning and milling combined processing can be divided into axial turning and milling, orthogonal turning and milling and ordinary turning and milling. Among them, axial turning and milling and orthogonal turning and milling are the most widely used turning and milling processes. Axial turning and milling cutters can machine not only the surface of the outer cylinder, but also the surface of the inner hole, because the rotation axes of the milling cutter and the workpiece are parallel to each other. Orthogonal turning and milling is very efficient when machining outer barrels because the axes of rotation of the milling cutter and the workpiece are perpendicular to each other. Orthogonal turn mills can machine smaller diameter bores. When processing the outer cylinder surface by orthogonal turning and milling, the longitudinal stroke is not limited and can even adapt to larger longitudinal feeds.

What are the advantages of turning and milling?

1. Shortening of R&D or production cycle

Turning and milling services can help customers shorten the research and development cycle. With the application of turning and milling compound CNC machine tools, the manufacturing chain of products or prototypes is shortened and production efficiency is significantly improved. Turn-milling machine tools can be equipped with a variety of special tools and new tool arrangements, which can reduce tool changing time and improve processing efficiency. Turning and milling combined processing can realize all processing or most parts processing in one clamping, which greatly shortens the manufacturing chain. In this way, products can be completed in a very short production cycle. With rapid turnaround of products or prototypes, customers can gain significant advantages during the R&D and production phases.

2. Improvement of accuracy

The accuracy of the product will be effectively improved. The clamping time of turning and milling machines is greatly reduced, and the machining accuracy is significantly improved. Because the reduction in clamping avoids the accumulation of tolerances due to position changes. At the same time, many turning and milling compound machine equipment have online detection functions, which can realize on-site detection and precision control of key data in the manufacturing process, thereby improving product accuracy.

3. Reduce production costs

Due to high production efficiency and reduced processing time, production costs are significantly reduced. In this way, turn and mill services can help customers save a lot of money on production or rapid prototyping. On the one hand, turning-milling combined processing reduces the auxiliary production time caused by changing clamps. Turning and milling, on the other hand, reduces fixtures and jigs

The manufacturing cycle and waiting time can significantly improve productivity. The high-strength integrated body design improves the gravity processing capability of difficult-to-cut materials.

Turning and milling machines are usually equipped with automatic feeding devices, which can perform continuous processing through automatic feeding to achieve single-machine assembly line production. Production time is one of the major components of cost as it is related to labor costs. As manufacturing time is reduced, customers can obtain low-cost and high-precision products.

Application areas

Generally speaking, customers will choose turn-milling services for high-speed and mass production of various small and complex parts. Materials used range from brass to steel, aluminum, stainless steel and Teflon, among others.

2 Replies to “What Is Mill-turn Machining?”

Thanks. Tell me more

thanks