Which product parts are more cost-effective to use CNC machining?

At present, the upgrading and application of CNC technology has fundamentally changed the traditional manufacturing industry. The iteration of microelectronics technology and computer technology has also brought new vitality to numerical control technology, and numerical control technology and numerical control equipment have become an important basis for industrial modernization.

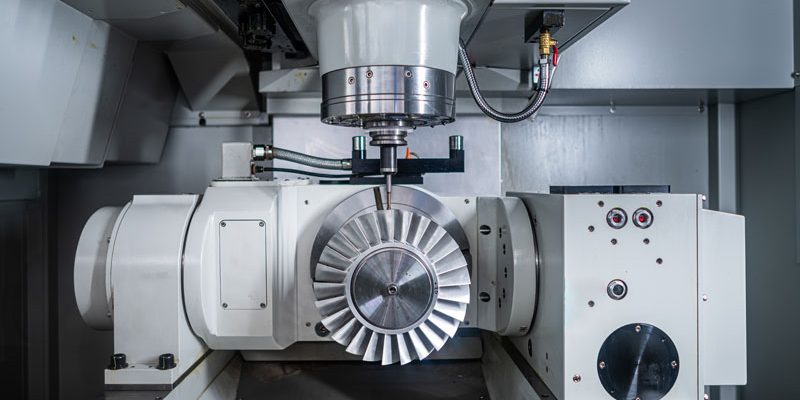

As a general subtractive manufacturing method, CNC machining has the characteristics of high efficiency, high precision and high flexibility. According to the design complexity of components, CNC machines with different axes can be used to remove part of the material until it is cut into finished parts. This fine rotating process can achieve extremely high dimensional accuracy and is compatible with many materials, including plastic, metal and wood, which can effectively solve complex, precise, small batch and changeable processing problems like molds, fully adapting to the needs of modern production .

Based on the advantages of precision, convenience, high efficiency and low cost, CNC is widely used in the processing of parts for daily use. So, which product parts are more cost-effective to use CNC machining? 2fprototypes summarizes a variety of parts suitable for CNC machining according to different classifications.

1.In the classification of materials, metal, plastic, wood, and other special materials such as ceramics, foam, and carbon fiber.

2.In the industry classification, aerospace industry, transportation industry, oil and gas industry, electronics industry, marine industry, medical industry, optical industry.

3.In part performance classification, parts with complex design, precise parts, one-piece or low-quantity parts, parts that need to be delivered quickly, parts with high surface finish requirements, parts with high prototype integrity, large size parts, repeated finishing part.

In CNC numerical control processing, 2fprototypes, which focuses on the mass production of prototype models, has shown significant advantages. The imported advanced numerical control equipment can effectively guarantee the three aspects of component size accuracy, position accuracy and shape accuracy. In addition, our rich experience in industrial application makes our CNC processing an economical choice for small batch and prototype production, allowing manufacturers to truly reduce costs and increase efficiency; without human intervention, the equipment can also perform 7*24H production to ensure efficient delivery; ultra-precise machining also allows components to achieve an excellent surface finish while retaining better strength and having better structural integrity.

In the 14 years of providing prototype production for the fields of automobiles, medical care, and electronic products, 2fprototypes has continued to increase scientific and technological research and development efforts, enhance corporate innovation capabilities, strive for excellence in craftsmanship, carefully polish technologies, and continue to promote intelligent upgrades and research and development of processes. Improve the company’s intelligent manufacturing level, production efficiency and yield rate, and expand the company’s core competitive advantage. At present, the company already has a complete industrial chain of product mold development, casting, and precision machining, and has accumulated rich industry experience and professional knowledge. It will continue to provide customers with high-quality and cost-effective products and help new products enter the market quickly.