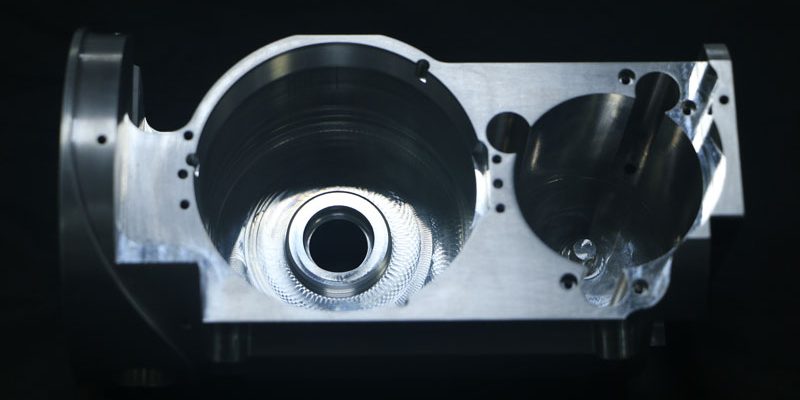

CNC prototype machining has high precision, can accurately control product quality, coupled with high production efficiency, it is a prototype machining method commonly used by many large prototype factories. However, there will still be differences in the machining accuracy of CNC prototypes, and the reasons for this can be analyzed from the following aspects.

1. Dimensional accuracy

Refers to the degree of conformity between the actual size of the processed part and the center of the tolerance zone of the part size. Dimensional accuracy is controlled by dimensional tolerances. Dimensional tolerance is the allowable variation in part size during cutting. In the case of the same basic size, the smaller the dimensional tolerance, the higher the dimensional accuracy.

2. Shape accuracy

Refers to the degree of conformity between the actual geometric shape of the processed part surface and the ideal geometric shape. The items for evaluating shape accuracy include straightness, flatness, roundness, cylindricity, and line profile. Shape accuracy is controlled by shape tolerances. Except for roundness and cylindricity, which are divided into 13 precision grades, the rest are divided into 12 precision grades. Level 1 is the highest and level 12 is the lowest.

3. Position accuracy

Refers to the difference in actual position accuracy between the relevant surfaces of the machined parts. The items for evaluating position accuracy include parallelism, perpendicularity, inclination, coaxiality, symmetry, position, circular runout and full runout. Position accuracy is controlled by position tolerance, and the position tolerance of each item is also divided into 12 precision grades.

4. Knive tools: The knive too used in the machining machine are generally tungsten steel knives. After this kind of knives are used several times, the knives will wear out, so there are also errors in the knives.

5. Manual tool setting: If there is a tool setting instrument, there will be no problem in tool setting. However, many small prototype factories, in order to save costs, choose to have no tool setting instrument when choosing a machine, and can only manually set the tool, so there are tolerances in terms of personnel. In order to ensure the accuracy of the prototype model, a tool setting instrument is installed on the CNC prototype machining equipment, which can not only accurately set the tool, but also greatly improve the work efficiency.

The above are the five aspects that affect the accuracy of prototypes CNC machining. The influence of each aspect will lead to differences in the accuracy of the final prototype model. Therefore, it is necessary to start with the machining accuracy of each aspect to make a prototype model that can achieve the best results.