Welcome to 2fprototypes!

2F Prototypes delivers high-precision CNC machining and rapid prototyping to produce reliable, high-quality medical device components

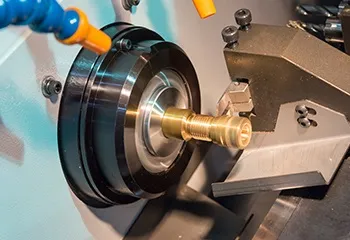

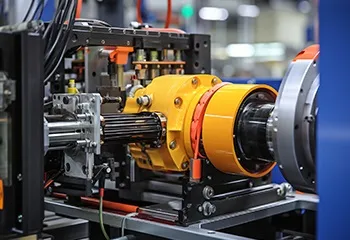

With extensive expertise in CNC machining, 2F Prototypes ensures the highest precision in manufacturing medical device components. We understand the critical nature of medical applications and guarantee consistent, reliable parts that meet stringent industry standards.

Our strict quality control process and adherence to ISO 9001 and IATF 16949 standards ensure that every medical component we manufacture is fully traceable, maintaining the quality and safety required in healthcare products.

2F Prototypes offers rapid prototyping and fast production times, allowing medical device manufacturers to accelerate their product development cycle. Our efficient process helps you move from design to delivery in the shortest time, reducing time-to-market for critical medical applications.

Aluminum Extrusion

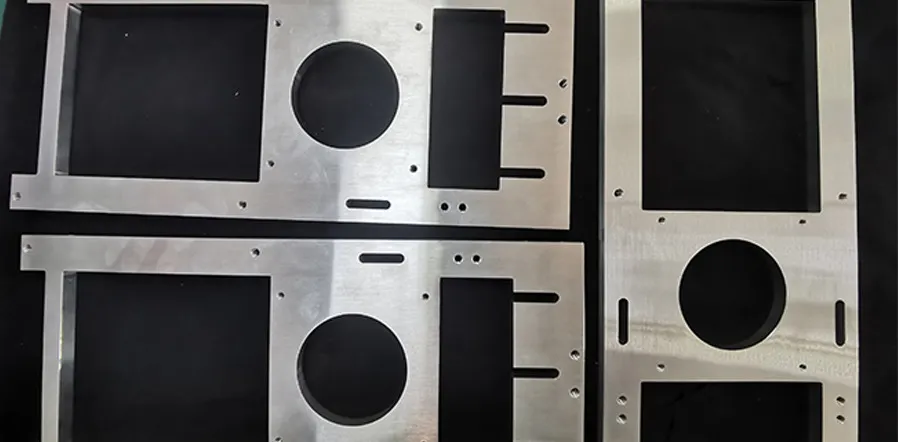

CNC Milling

CNC Turning

Die Casting

Laser cutting

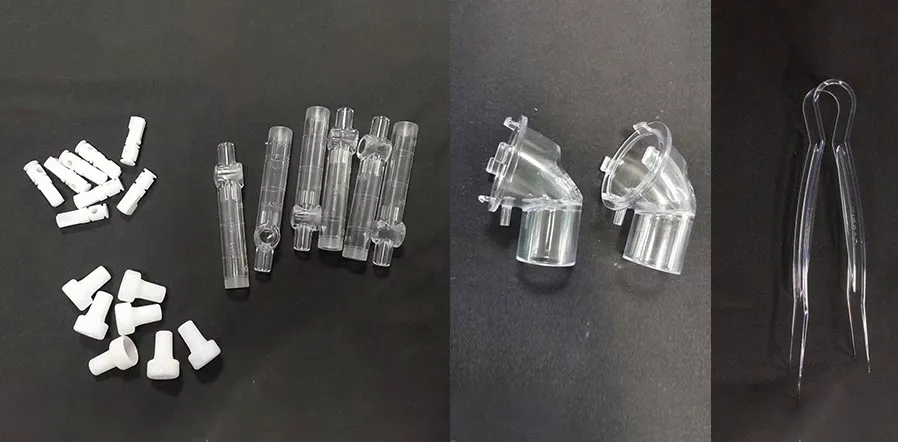

Plastic Injection Molding

Sheet Metal Bending

Sheet Metal Stamping

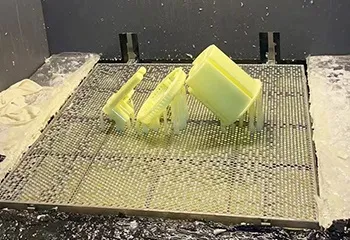

SLA SLM SLS 3D Printing

Vacuum Casting

At 2F Prototypes, we are committed to the highest standards of precision and quality in medical device manufacturing. With our ISO 13485 certification, we ensure that every medical component we produce meets stringent regulatory requirements and upholds safety and performance standards. Our commitment to quality guarantees that our clients receive reliable, safe, and effective medical devices, making us a trusted partner in the healthcare industry.

2F Prototypes offers a variety of high-quality industrial-grade materials and surface treatment options designed to meet the stringent requirements of medical device components. With our advanced manufacturing capabilities, we can provide flexible solutions from prototype to full-scale production while ensuring compliance with regulatory standards.

2F Prototypes provides a wide range of biocompatible materials suitable for medical device prototypes and mass production of parts:

2F Prototypes offers a variety of medical-grade surface treatments suitable for both metal and plastic medical device components:

At 2F Prototypes, we enhance the production of a wide range of medical device components. Common medical device applications we undertake include:

Communicate your requirements with us and we will contact you as soon as possible