Welcome to 2fprototypes!

Laser Cutting, Bending & Stamping Services

Upload your drawings an instant quote for custom sheet metal prototypes and production parts

Our sheet metal fabrication services integrate cutting-edge technologies to ensure precision

and efficiency at every stage, from design to finished product.

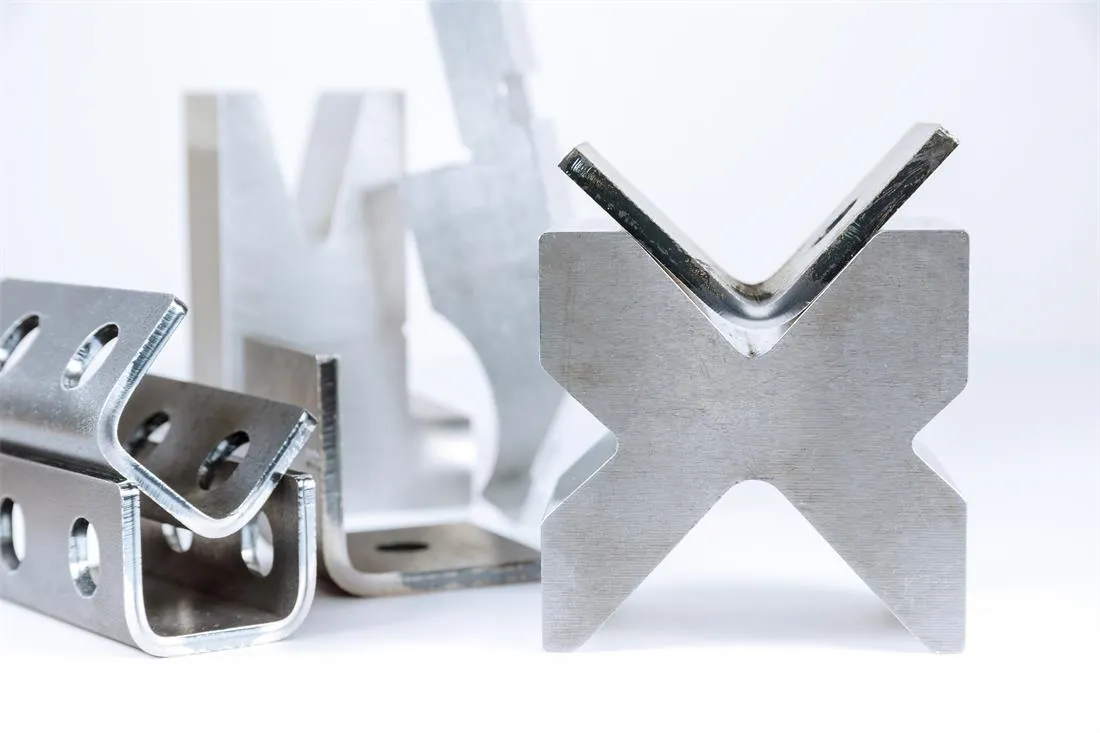

Capabilities: Precision angles, complex bends, and forming of metals like steel, aluminum, and stainless steel.

Materials: Steel, aluminum, stainless steel, copper, and brass.

Applications: Automotive parts, brackets, enclosures, and frames.

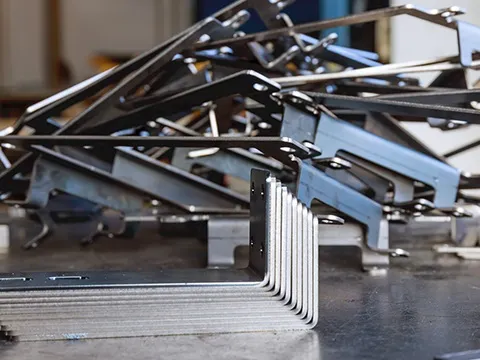

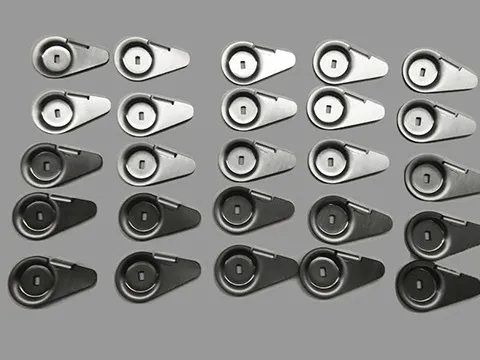

Capabilities: High-speed, high-volume production of complex parts.

Materials: Steel, aluminum, copper, brass, and galvanized steel.

Applications: Automotive parts, consumer electronics, industrial components, and enclosures.

Sheet Metal Bending Parts

Sheet Metal Bending Parts

Sheet Metal Stamping Parts

Sheet Metal Stamping Parts

At 2F Prototypes, our factory is equipped with advanced stamping and bending equipment capable of producing high-precision sheet metal components.

Our stamping machines range from 25 tons to 120 tons, allowing us to handle a wide variety of materials, thicknesses, and sizes.

Whether it’s for small, complex parts or high-volume production, our stamping presses ensure consistent quality and efficiency.

In addition, our CNC bending capabilities provide precise bends and complex shapes to meet your exact specifications. By utilizing advanced machinery, we are able to achieve tight tolerances and

create durable parts for industries such as automotive, aerospace, industrial machinery, and more.

From prototyping to low-volume production, we are equipped to deliver cost-effective solutions while maintaining the highest quality standards across all sheet metal fabrication processes.

Steel

Aluminum

lron

Stainless Steel

Copper

Stainless steel

Aluminum

Brass

Cold-rolled steel

Hot-rolled steel

Galvanized

Other metal alloys

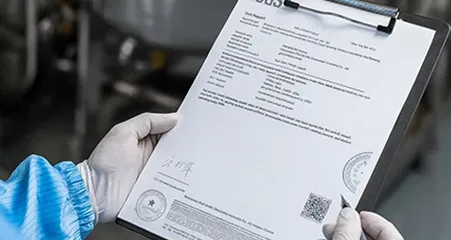

Certified Quality - Certified with AS9100D, IATF 16949: 2016, ISO 9001: 2015, and ISO 13485: 2016.

No Minimum Order - Flexible order quantities, from prototypes to full-scale production.

Prototyping to Production - Seamless transition from prototypes to large-scale manufacturing.

Fast Sample Delivery - 1 samples delivered as fast as 2 weeks.

With 17 years of expertise, we deliver high-quality, precision fabrication.

Customer Satisfaction Guarantee - Our Service Philosophy

We use advanced equipment like CMMs, laser scanners, and height gauges for precise inspections throughout production. We cheke dimensions, surface quality, and overall accuracy to ensure every part meets your specifications, using tools like micrometers and surface roughness testers.

All products undergo strict in-process and final inspections. We provide official quality reports with key dimension data to ensure traceability and verify compliance with your specifications.

Before delivery, we'll send you detailed product photos along with packaging details and quantity information for your approval. Shipment will proceed only after we receive your confirmation.

Communicate your requirements with us and we will contact you as soon as possible