Welcome to 2fprototypes!

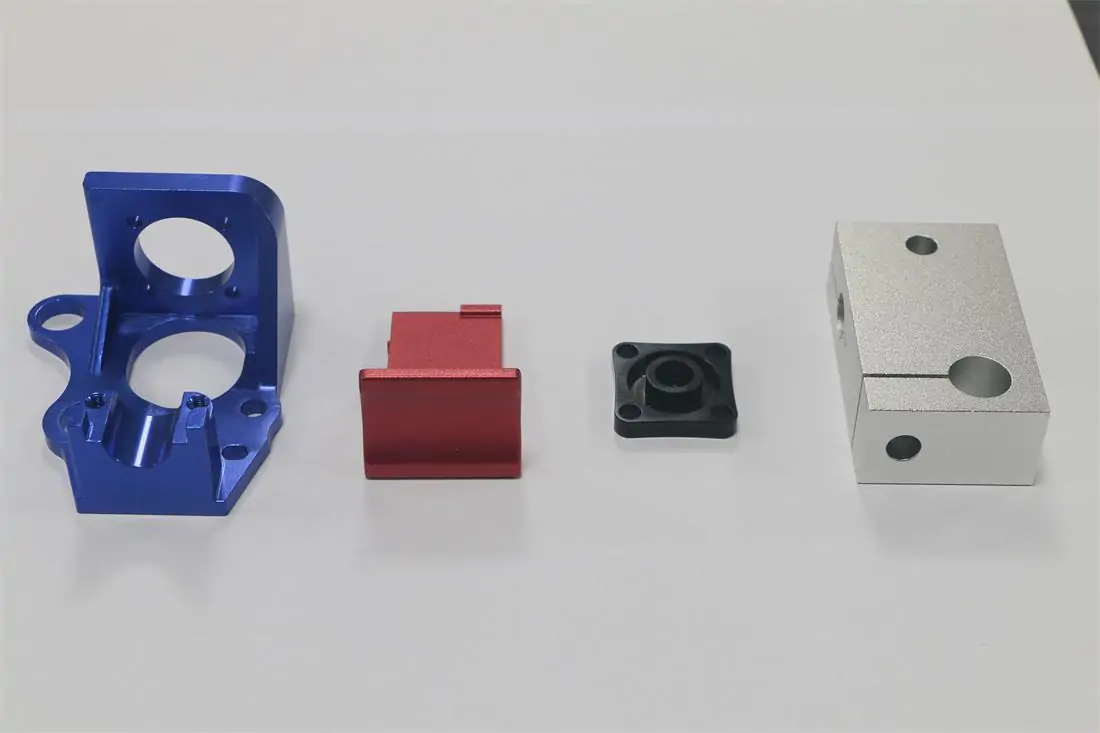

Polishing, Anodizing, Painting & More

Surface finishing is a processing that can change the finished part's surface to specific color, appearance, property.

It gives the finished part different properties of resistance to corrosion, hardness, conductivity, etc. that out of the material itself.

Surface finishing is the final step in your manufacturing process, enhancing both the appearance and functionality of your parts. Whether you're polishing for a sleek look or coating for durability, our finishing services help bring your product to the next level.

A proper surface finish improves not only the visual appeal, but also the wear resistance, corrosion protection, and overall lifespan of your parts. It ensures your prototypes and end-use products perform as well as they look.

Spray painting

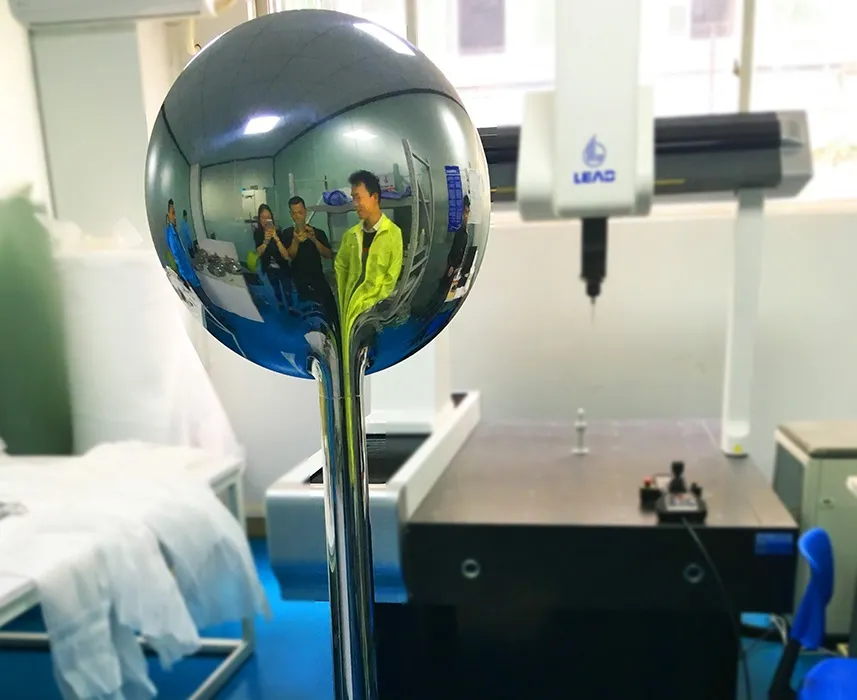

Mirror Polish

Powder coating

Anodizing

Communicate your requirements with us and we will contact you as soon as possible