Welcome to 2fprototypes!

✅Custom metal & plastic parts delivery as fast as within days

✅From prototype to low-volume runs (1–1000+ units)

✅3-Axis, 4-Axis, 5-Axis CNC machining capabilities

✅Get a Free Quote in 24h

Precision CNC machining with expert capabilities for complex, high-tolerance parts — from prototype

to production, ensuring superior quality and fast turnarounds. Certified to ISO 9001, ISO 13485, IATF 16949, and AS9100D,

we deliver reliable, industry-compliant parts for the aerospace sector.

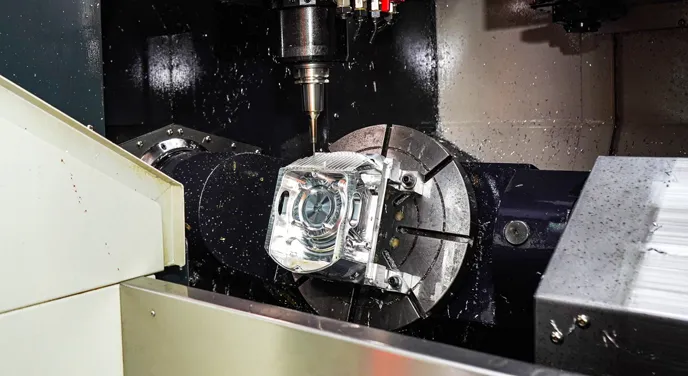

Advanced 3-axis-, 4-axis & 5-axis milling capabilities. From prototype to production — tight tolerence, fast, and reliable.

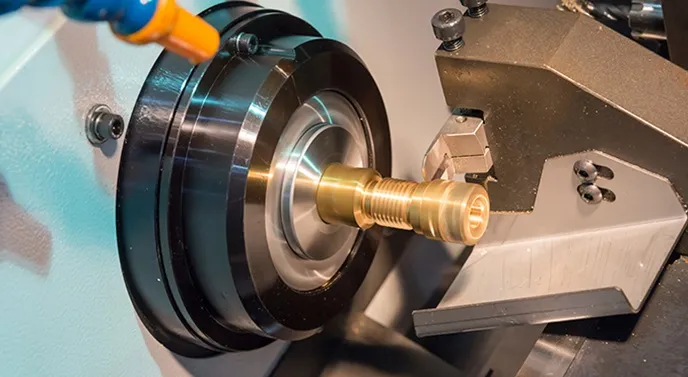

High-performance CNC turning & mill-turn solutions. Consistent precision for complex geometries and flexible runs.

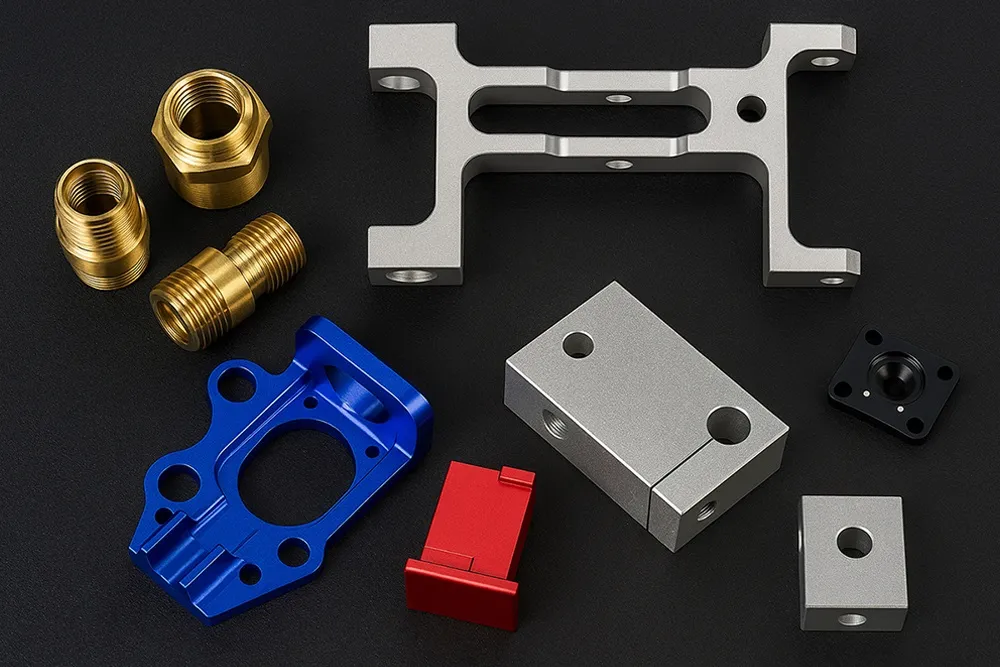

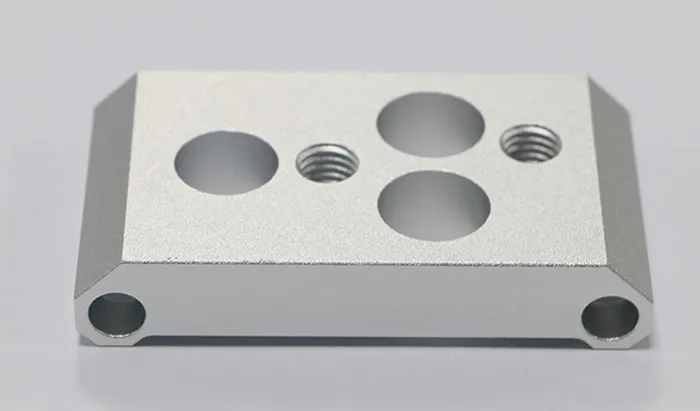

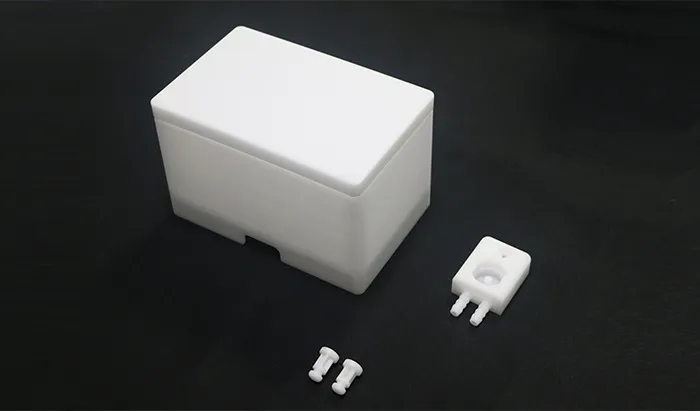

A selection of our signature CNC machined parts for your reference

Material: ABS

Process: CNC Milling

Surface Finish: Spray painting

Material: Steel

Process: CNC Turning

Surface Finish: Mirror Polish

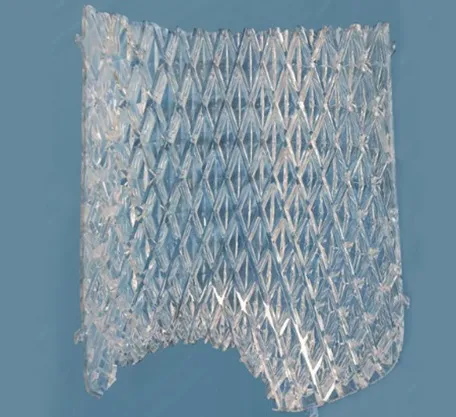

Material: PMMA

Process: CNC Machining

Surface Finish: Mirror polish

Material: Aluminum

Process: 5-axis CNC Machining

Surface Finish: As Machined

We are equipped with 3-, 4-, and 5-axis CNC machining capabilities, using certified materials and offering a variety of surface

finishes, ensuring tight tolerances, reliable quality, fast delivery, and on-demand production to meet your needs.

| General Machining Information | |||||

| 3-Axis Milling | 3+2-Axis Milling | 4-Axis Milling | 5-Axis Milling | Turning | |

| Max Processing Strokes | 2600 x 2600 mm 102.4 x 102.4 in |

1000 x 650 x 600 mm 39.4 x 25.6 x 23.6 in |

850 x 550 x 600 mm 33.5 x 21.7 x 23.6 in |

660 x 1020 x 500 mm 26 x 40.2 x 19.7 in |

860 x 300 mm 33.9 x 11.8 in |

| Precision | ±0.015mm | ±0.015mm | ±0.015mm | 0.003mm-0.005mm | ±0.01mm |

| Max Speed | 15,000 | 20,000 | 20,000 | 24,000 | 4,500 |

Our CNC machining materials are selected for their superior strength, lightweight properties, and

excellent corrosion resistance. These materials, including various metals and plastics, ensure precision, durability, and high

performance across a range of applications.

Aluminum (Aluminum 7075-T7351 , Aluminum 6061-T651 , Aluminum 7075-T651 ,Aluminum 6082-T651 ,Aluminum 6060 )

Stainless steel

Mild steel

Copper

Titanium

Brass

Alloy steel

Tool steel

Invar 36

Inconel

ABS

POM (Delrin/Acetal)

Nylon

PPSU

PVC

PEEK

PTFE (Teflon)

Polycarbonate

Polyethylene

PMMA (Acrylic)

PET

Polypropylene

G-10

FR4

PEI

Certified to ISO 9001, ISO 13485, IATF 16949, and AS9100D — ensuring quality for medical, automotive, aerospace, and other precision industries.

Tight tolerances down to 0.003–0.005 mm — ensuring outstanding precision for complex parts.

Comprehensive in-house quality control — with advanced height gauges, YVM, and CMM systems.

145+ CNC machines (3-, 4-, and full 5-axis) — enabling scalable production with exceptional accuracy.

Fully owned production facility — fast turnaround and flexible scheduling.

Interactive quotes within 24 hours — responsive, professional support from day one.

Customer-first approach — committed to your satisfaction through every step.

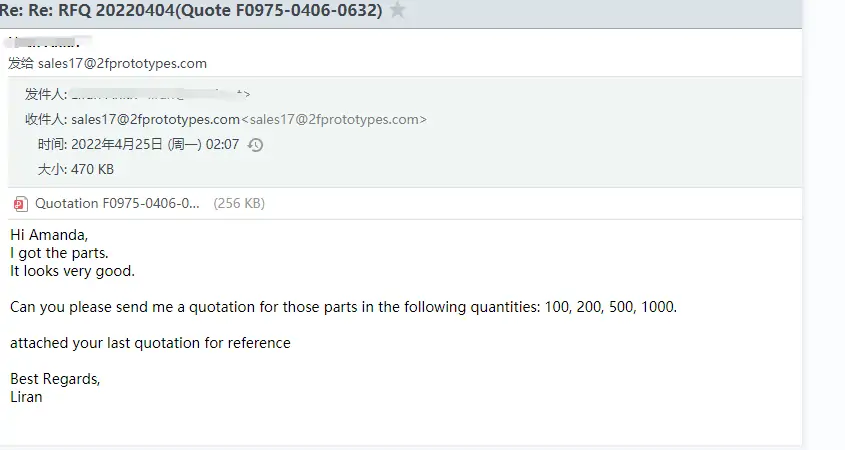

Hear directly from the companies we’ve served — real feedback that reflects

our commitment to quality, reliability, and trust.

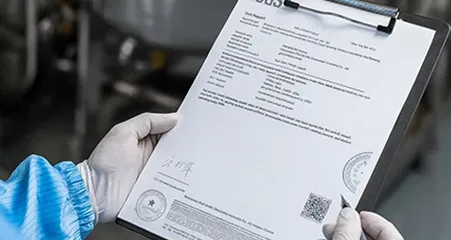

We are equipped with advanced dimensional inspection equipment, including height gauges, visual measuring systems, and CMMs, to ensure product accuracy and consistency.

All products undergo strict in-process and final inspections. We provide official quality reports with key dimension data to ensure traceability and verify compliance with your specifications.

Before delivery, we'll send you detailed product photos along with packaging details and quantity information for your approval. Shipment will proceed only after we receive your confirmation.

Communicate your requirements with us and we will contact you as soon as possible