Welcome to 2fprototypes!

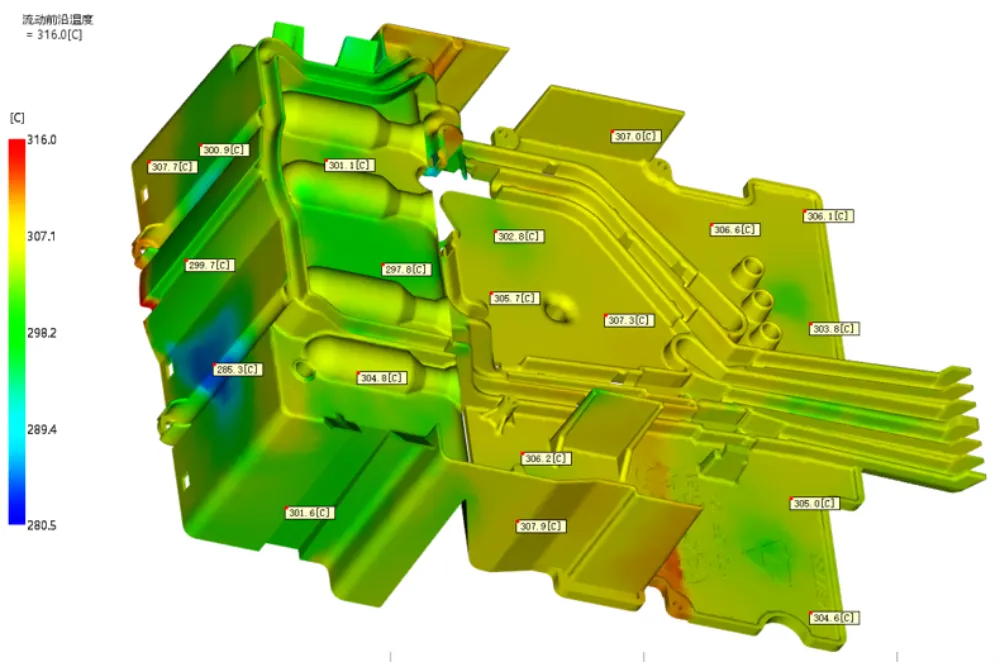

Design: Our skilled engineers collaborate with you to fully understand your specific needs, ensuring a custom mold design tailored to your project using the latest CAD software.

Material Selection: We use high-quality materials such as steel and aluminum, selected based on your project’s requirements and the expected lifespan of the mold

Machining: Precision CNC machining is employed to craft the mold, ensuring tight tolerances and perfect alignment for high-quality results.

Testing and Adjustment: Before mass production, we conduct rigorous testing on the mold, making necessary adjustments to ensure optimal performance.

Production: After finalizing the mold, it’s ready for mass production, ensuring consistent part quality and reliability.

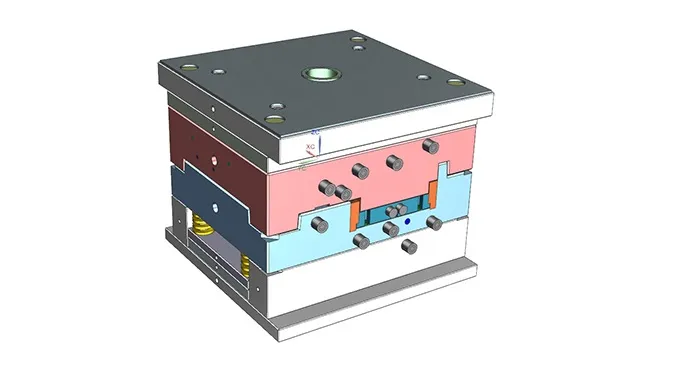

2fprototypes is capable to provide our customers with diversified molds for tools for both plastic and metal parts manufacturing.

With our internal die-making equipment and superior suppliers, our tool and die are

made by CNC machining, sheet metal fabrication, and stamping. Whether you need rapid tooling for short-run production

or dies for mass production, 2fprototypes is your smart choice.

Plastic injection molds usually are made of aluminum or steel. They are used to make parts from glass-filled nylon, acrylic, silicone, etc. The application of plastic injection molds includes almost all industries from complicated automotive safety components to simple pen shell.

Metal powder injection molding is an effective way to volume metal parts in small sizes. The materials of MIM mold mainly include stainless steel, 304 steel, 314 steel, 316L, titanium alloy, etc.

Vacuum casting mold is use for making small batches of plastic parts. A custom mold can last between 30 and 50 shots. Vacuum casting molds made by soft silicone and it has a shorter production time, which means the high efficiency for small volume production.

Stamping die is a special process equipment for processing metal materials into parts (or semi-finished products) in cold stamping. 2fprototypes has the ability to open stamping dies for the manufacture of large-volume metal parts.

2fprototypes offers a wide range of mold solutions for both plastic and metal part production. With over a decade of experience

in mold design, manufacturing, and export, we build high-precision tooling using in-house

CNC machining, EDM, polishing, and other advanced processes. Whether you need rapid tooling for

prototyping or durable molds for high-volume production, 2fprototypes is your trusted partner.

| CNC Tooling & EDM Machine Specification | |||||

| Brand | Specification | Quantity | Processing Stroke | Precision (MM) | Origin |

| DMG MORI 3000rpm((CNC Machine)) | NVD4000-DCG | 1 | X:750 Y:450 Z:450 0.003 | 0.003 | Japan |

| MIKRON 20000rpm (CNC Machine) |

HEM1000 | 1 | X:1060 Y:660 Z:450 | 0.003 | Switzerland |

| Makino(EDM Machine) | MGC3 | 3 | X:800 Y:550 Z:350 | 0.01 | Japan |

| Sodick (EDM Machine) |

AD30LS | 1 | X:300 Y:200 Z:15 | Mirror Surface ±0.005 | Japan |

We work with a variety of materials to create the perfect mold for your project. The most common materials we use include

Ideal for high-volume production and long-lasting molds, providing excellent durability and wear resistance.

A lighter and more cost-effective option, suitable for lower-volume production and rapid prototyping.

Communicate your requirements with us and we will contact you as soon as possible