Welcome to 2fprototypes!

✅From tooling to production, rapid prototyping to mass production

✅1unit - 10,000+ units, flexible for low to high volume

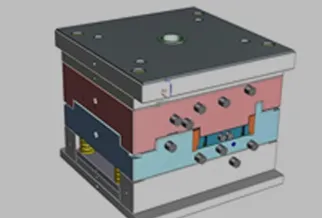

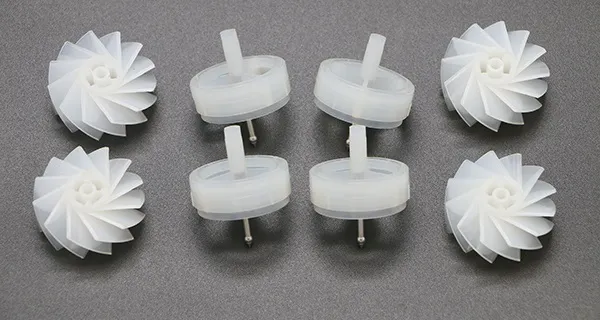

Plastic injection molding is designed especially for the mass production of plastic parts by repeatedly

using the same mold. Consistent color, structure, appearance is the features for injection molded parts. Hundreds of thousands of custom parts are produced by machines.

The cost of per part decrease with higher quantity manufacturing runs.

Plastic injection molding is a manufacturing process that involves injecting high-pressure, molten thermoplastic into a custom mold to create precise parts.

Insert molding is an injection molding process in which thermoplastic material is molded around pre-positioned inserts—such as metal pins, threaded fasteners, or electronic components—placed inside the mold.

Overmolding is an advanced injection molding process where one plastic material is molded over another to create a single, unified component.

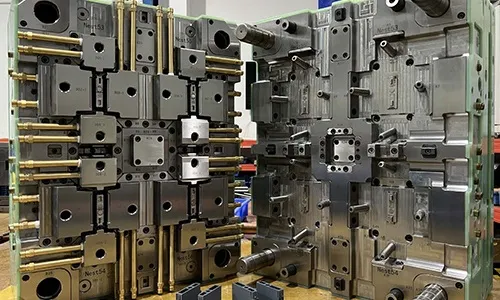

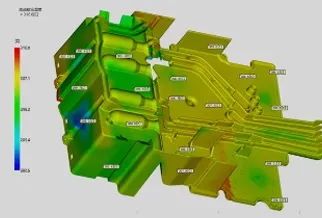

At 2F Prototypes, we provide precision mold-making services with in-house manufacturing, ensuring customized solutions, reduced lead times, and optimized costs for your production needs.

2f prototypes’ customers come from all walks of life around the world. The processed products cover the medical equipment industry,

auto parts industry, aviation and shipping industry, industrial machinery manufacturing, electronic and

electrical manufacturing, fitness equipment industry, etc.

From making prototypes to opening molds to mass production, 2fprototyps receives hundreds of orders from all over the

world every day for production.

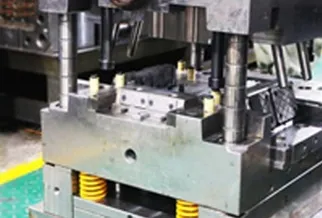

We have injection molding machines ranging from 80T to 1600T, allowing us to handle a wide range of mold sizes and types. With our in-house manufacturing capabilities, we can better control production schedules, ensure stringent quality control, and meet delivery deadlines. The higher tonnage machines support larger and more complex molds, ensuring tight tolerances and consistent, high-quality parts at optimal production costs.

CNC Tooling

We have domestic and imported tooling from Switzerland and Japan.

Precision: ±0.005mm

RPM: 2,400–20,000

2fprototypes provides various materials for our customers’ choice.

At 2F Prototypes, we provide a wide range of surface finishing options for injection molded parts to

enhance their appearance, durability, and functionality.

Mirror Finish Satin Finish Textured Finish Matte Finish

High Gloss Semi Gloss Low Gloss Matte

A-1 / A-2 / A-3 B-1 / B-2 / B-3 C-1 / C-2 / C-3 D-1 / D-2 / D-3

0.012 - 0.05 0.05 - 0.32 0.35 - 0.70 0.80 - 3.20

Consumer electronics shell Automotive interiors Medical device enclosures Industrial covers, grips

Fine Texture Medium Texture Standard Texture Heavy Texture

Satin Matte Grainy Rough

VDI 12 / VDI 15 VDI 18 / VDI 21 VDI 24 / VDI 27 VDI 30 / VDI 33

0.4 - 0.8 0.8 - 1.2 1.2 - 1.6 1.6 - 2.4

Home appliance panels Power tool housings Automotive dashboard parts Industrial and outdoor casings

At 2F Prototypes, we offer flexible injection molding solutions tailored to your production needs, from

prototypes to low-volume and mass production runs.

Our prototype injection molding services allow for rapid, high-quality prototypes to validate your designs before moving to full production. With quick lead times, a variety of materials, and expert DFM support, we ensure that your parts are produced efficiently and functionally tested.

2F Prototypes offers low-volume injection molding with fast, cost-effective production runs of complex parts. Using aluminum tooling, we ensure quality control and flexible manufacturing to meet demand, whether it's hundreds or thousands of parts.

For high-volume orders, we provide efficient, precise injection molding to mass-produce large quantities of identical parts with tight tolerances. With advanced equipment and strict quality control, we ensure consistent results across a wide variety of materials for your specific needs.

Injection molding is a highly efficient process for mass-producing plastic parts with high precision and low cost. It is widely used across various industries for producing identical parts, making it essential for applications that require tight tolerances. Here are some common applications:

Communicate your requirements with us and we will contact you as soon as possible