Welcome to 2fprototypes!

SLA, SLS, SLM 3D printing and vacuum casting are available. Find the ideal way for your prototypes.

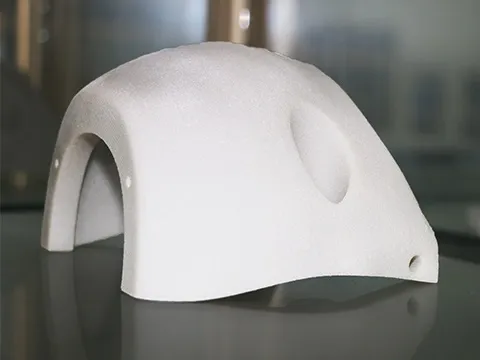

SLS fuses powdered material layer by layer using a laser, producing robust and durable parts. It’s excellent for complex geometries and end-use applications.

SLM melts metal powders with a laser to create high-strength, intricate metal parts. This process is ideal for aerospace, medical, and industrial applications.

SLA utilizes a laser to cure liquid resin into solid parts with high precision and smooth surfaces. Ideal for detailed prototypes and intricate designs.

HP MJF uses a fusing agent and heat to create strong, functional parts with fine details and excellent mechanical properties.

1. SLS – Common Nylon-Based Materials

PA 12 (Nylon 12)

PA 11

PA + GF (Glass-Filled Nylon)

TPU (Thermoplastic Polyurethane)

PPS (Polyphenylene Sulfide)

2.SLA – Resin-Based Materials

Standard Resin

Tough Resin

Clear Resin

Flexible Resin

Castable Resin

High Temp Resin

Stainless Steel (316L)

Aluminum Alloy (AlSi10Mg)

Titanium Alloy (Ti6Al4V)

Tool Steel (Maraging Steel)

Cobalt-Chrome Alloy

Inconel (Nickel Alloy)

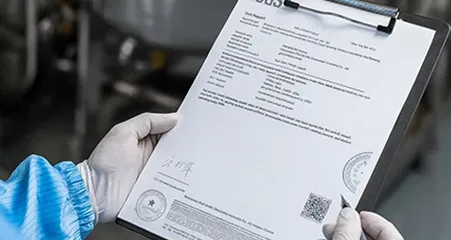

Certified Quality Assurance :Backed by AS9100D, IATF 16949, ISO 9001, and ISO 13485, we meet global standards for demanding industries.

omprehensive 3D Printing Capabilities :We offer SLS, SLA, and SLM technologies to cover both plastic and metal part production.

No Minimum Order Quantity :From one-off prototypes to small batch production — we support all project sizes with flexibility.

Fast Lead Times Within Days:T1 samples delivered in as fast as 2 weeks, helping you speed up development and decision-making.

One-Stop Material and Finishes Support:Access a wide range of plastics, metals, and post-processing options — all in one place.

We are equipped with advanced dimensional inspection equipment, including height gauges, visual measuring systems, and CMMs, to ensure product accuracy and consistency.

All products undergo strict in-process and final inspections. We provide official quality reports with key dimension data to ensure traceability and verify compliance with your specifications.

Before delivery, we'll send you detailed product photos along with packaging details and quantity information for your approval. Shipment will proceed only after we receive your confirmation.

Communicate your requirements with us and we will contact you as soon as possible