Welcome to 2fprototypes!

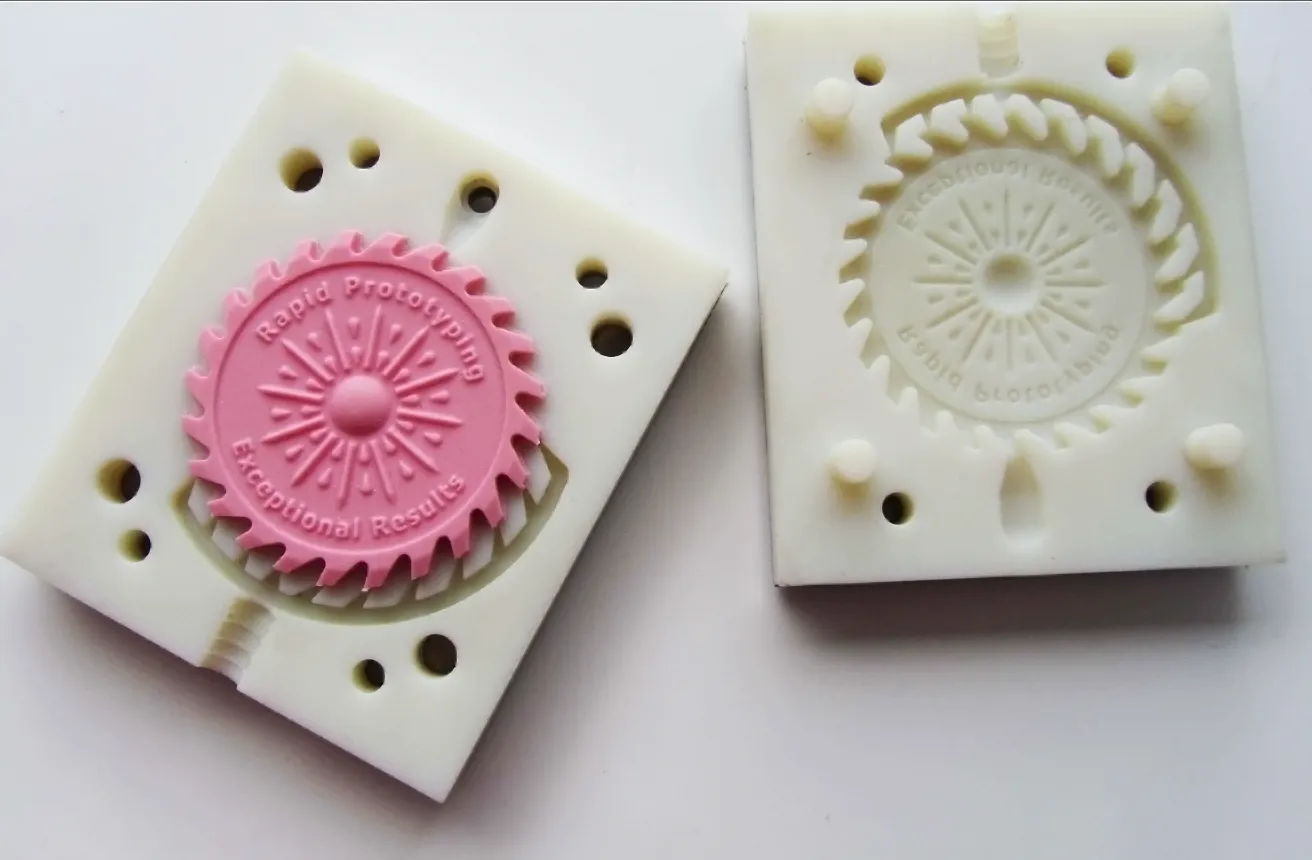

Vacuum casting is a low-volume manufacturing process that uses silicone molds and polyurethane resins to produce high-quality plastic parts. It’s ideal for creating prototypes and short-run production parts that closely replicate injection-molded finishes and performance.

This process is perfect when you need cost-effective, high-detail, and fast-turnaround parts without investing in expensive tooling. Vacuum casting offers excellent surface finish, material versatility, and dimensional accuracy — making it an ideal bridge between prototyping and mass production.

Part 1

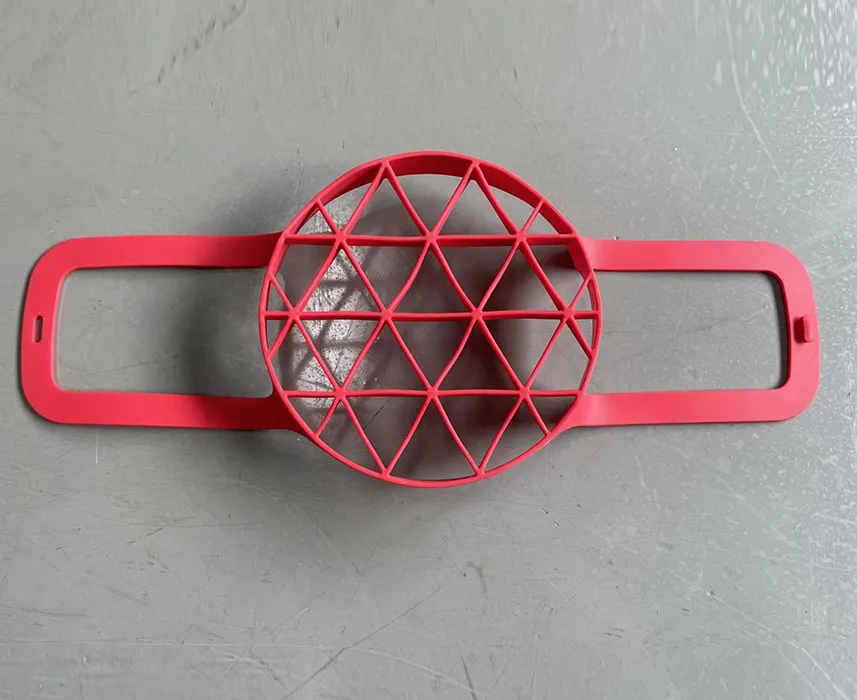

Part 2

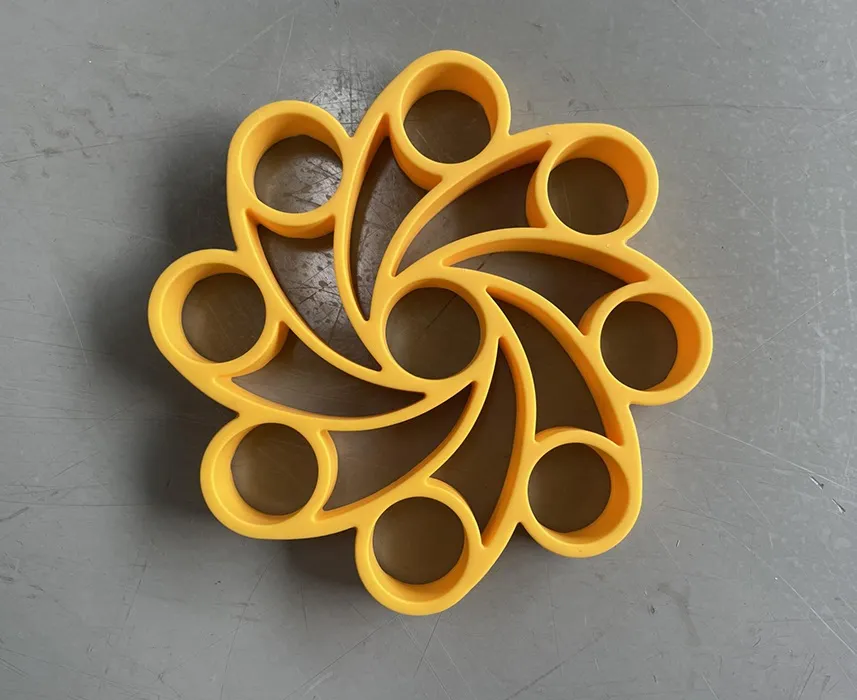

Part 3

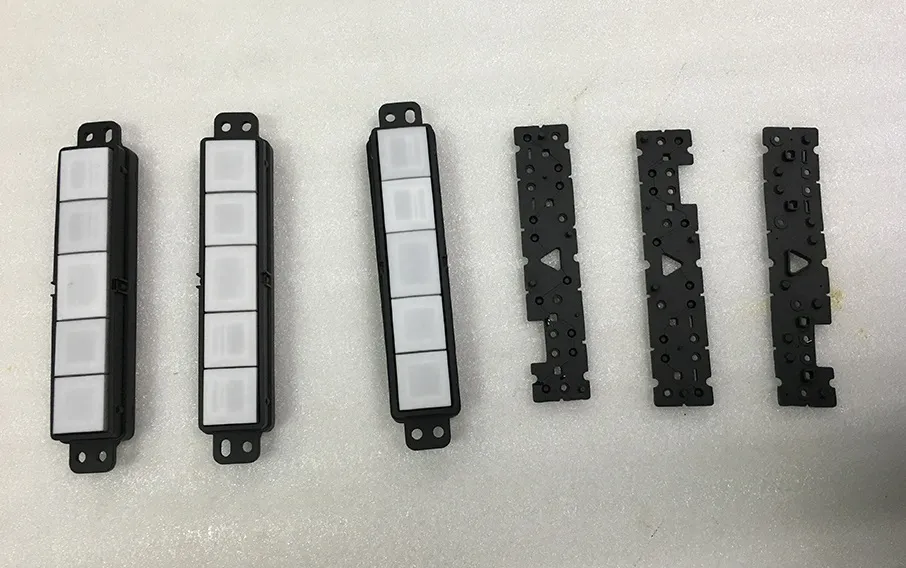

Part 4

Vacuum casting is a versatile process used across multiple industries for functional prototypes, visual mockups, and low-volume production. In consumer electronics and products, it’s perfect for

producing housings, enclosures, grips, and ergonomic parts. The medical industry relies on vacuum casting for testing device enclosures, handles,

and early-stage trial components. In the automotive sector, it supports the development of interior parts, dashboard elements,

and concept components. It’s also widely used in robotics, wearables, and startup hardware development, where fast, accurate,

and cost-effective part validation is critical before investing in injection molding.

Vacuum casting resins are specially formulated to simulate common injection molding materials like

•ABS

•PP

•PC

•PMMA

•TPE

This allows you to test your product’s fit, form, and function before investing in hard tooling — with results that closely resemble the final molded parts.

We offer polyurethane materials with a variety of performance characteristics:

•Rigid: High strength and impact resistance

•Flexible: Rubber-like materials for soft-touch or sealing parts

•Transparent: Clear resins ideal for lenses or housings

•High Temperature: Heat-resistant options for demanding applications

Whatever your project needs, we can help select the right resin to match it

Low Cost for Small Batches – No expensive steel tooling required

Excellent Surface Finish – Smooth and ready for painting or coating

Fast Turnaround – T1 samples in as little as 7–10 days

Material Versatility – Simulates ABS, PP, PC, rubber, etc.

Dimensional Accuracy – High-fidelity replication using silicone molds

Ideal for Prototyping & Testing – Validate design before investing in molds

2F Prototypes is certified with ISO 9001, AS9100D, ISO 13485, and IATF 16949. Our strict quality control ensures accurate, durable, and high-performance parts for every vacuum casting project.

We provide high-quality elastomeric and rigid polyurethane materials for complex parts. From design to casting, our team ensures your prototypes and low-volume production parts meet tight tolerances and design intent.

With over 17 years of manufacturing experience, our team delivers end-to-end vacuum casting services — including material selection, mold making, surface finishing, and final inspection — all under one roof.

Communicate your requirements with us and we will contact you as soon as possible