Plastic injection molding is one of the most widely used manufacturing processes in the world, responsible for producing everything from small household items to complex automotive components. This process allows manufacturers to create parts quickly and with precision, making it indispensable in industries such as consumer electronics, automotive, and medical devices.

How Does Plastic Injection Molding Work?

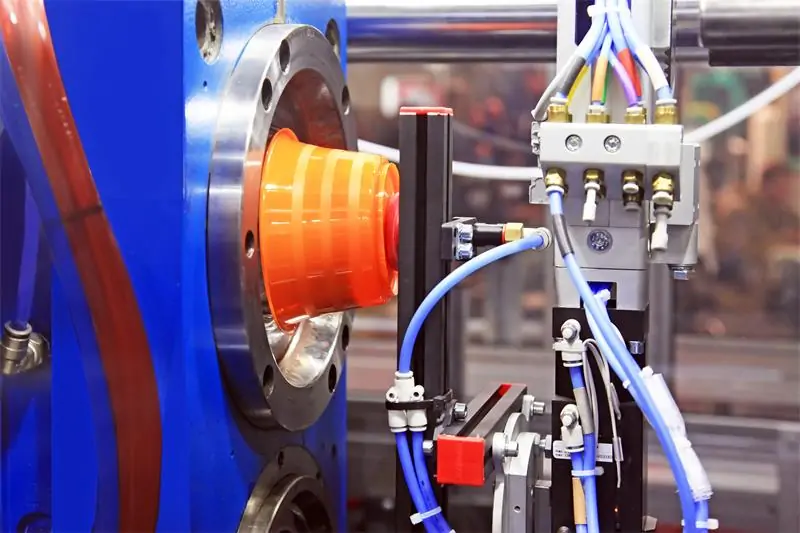

Plastic injection molding involves injecting molten plastic into a mold under high pressure. Once cooled, the plastic hardens and takes the shape of the mold, producing a finished part. It's an efficient process that allows for both high-volume production and tight tolerances.

- ① Applications of Plastic Injection Molding:

- ② Automotive Industry: Car parts, from bumpers and dashboards to clips and fasteners, are often made through injection molding.

- ③ Consumer Electronics: Injection molding is used to produce parts for phones, computers, and televisions, such as housings and buttons.

- ④ Medical Devices: Devices like syringes, medical containers, and diagnostic tools are made using injection molding because of its precision and ability to handle specific materials.

Why is Plastic Injection Molding Ideal for Mass Production?

- ⑤ High Efficiency: Once a mold is created, injection molding can produce thousands of identical parts in a short period, which makes it cost-effective for mass production.

- ⑥ Material Flexibility: Injection molding can accommodate various types of plastic, including thermoplastics and thermosets, allowing for a wide range of properties and applications.

- ⑦ Precision and Accuracy: The process ensures that each part is created with high accuracy, with tolerances as low as ±0.005 mm, making it ideal for creating parts that need to fit perfectly.

For instance, in the medical device industry, components such as syringes and medical enclosures are produced using injection molding to ensure they meet strict hygiene and safety standards. Similarly, automotive parts like dashboard components are manufactured using this process for both functionality and durability.

In a word, plastic injection molding provides an efficient, cost-effective way to mass-produce plastic parts with precision. Its versatility and ability to handle high volumes of production make it an essential process for many industries, including automotive, medical, and consumer electronics.