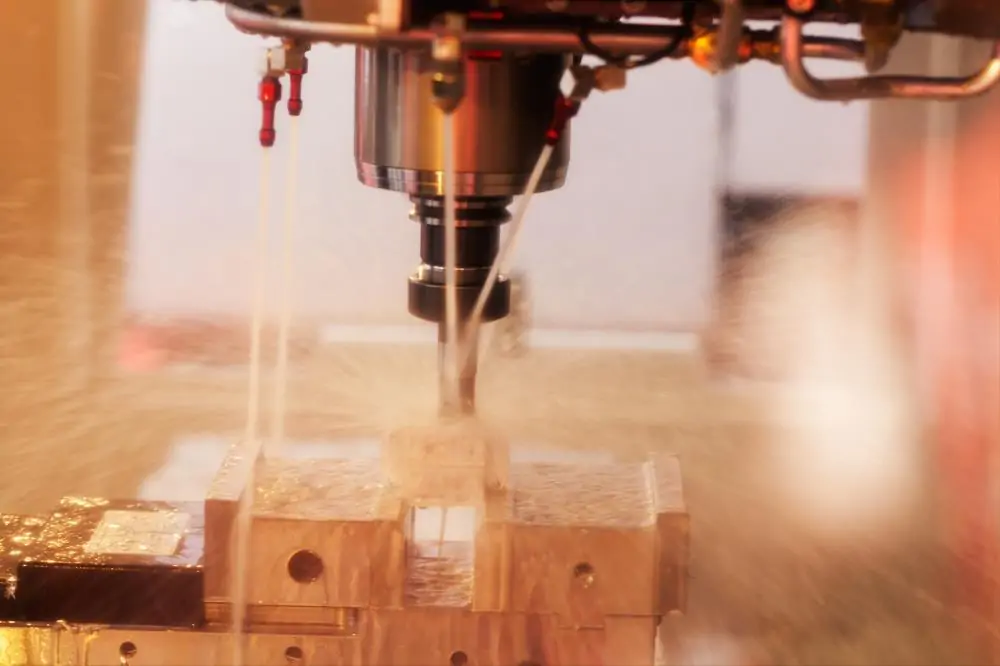

CNC milling is one of the most commonly used manufacturing processes, employing rotary cutters to remove material from a workpiece to create custom shapes and designs. It is known for its high precision and versatility, which is why it is used across various industries for producing functional parts.

What Is CNC Milling?

In CNC milling, a rotating cutter is used to remove material from a workpiece, which is held in place by a machine fixture. The cutter can be moved in multiple directions, allowing it to create precise and intricate shapes.

Applications of CNC Milling:

- Aerospace: CNC milling is used to produce critical parts such as turbine blades, brackets, and frames for aircraft and spacecraft.

- Automotive: Parts like engine components, transmission housings, and suspension parts are commonly made using CNC milling.

- Medical Devices: Surgical instruments and implants, such as titanium screws and knee replacements, are often produced using CNC milling for precision and durability.

Why Choose CNC Milling?

- High Precision: CNC mills are capable of producing parts with tight tolerances, making them perfect for applications where accuracy is crucial.

- Material Flexibility: CNC milling works with a variety of materials, including metals, plastics, and composites.

- Complex Geometries: The versatility of CNC milling allows it to create intricate, complex parts that require multiple axes of motion.

In aerospace, CNC milling is critical for manufacturing parts like turbine blades, where the accuracy of each part is essential for performance and safety.

Summary, CNC milling is an essential tool for creating complex, high-precision parts. Whether you're in aerospace, medical, or automotive manufacturing, CNC milling offers unparalleled accuracy and versatility.